Select Additive Technologies

Select Additive Technologies is your bridge between machining and additive technologies. Builders that are included are One Click Metal, Desktop Metal, and Stratasys.

Desktop Metal Products

Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with end-to-end metal 3D printing solutions. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make metal 3D printing an essential tool for engineers and manufacturers around the world.

Fiber

Fiber combines the performance of continuous fiber with the ease of FFF printing to produce high-performance parts that are stronger than steel, lighter than aluminum and can operate in temps up to 250 ºC. The continuous fiber tape is applied along critical load path is in Micro Automated Fier Placement and is then laminated to build reinforced sections that are two times stronger than steel.

MORE INFO »

Shop System

The world's 1st metal binder letting system designed for machine shops and is built to fit seamlessly into your workflow. The Shop System contains all pieces of equipment your shop needs to begin binder jetting - print to sintering. Produce high-quality metal parts up to 10x faster with its high-speed, single-pass print engine and the ability to produce up to 70kg of metal parts per day.

MORE INFO »

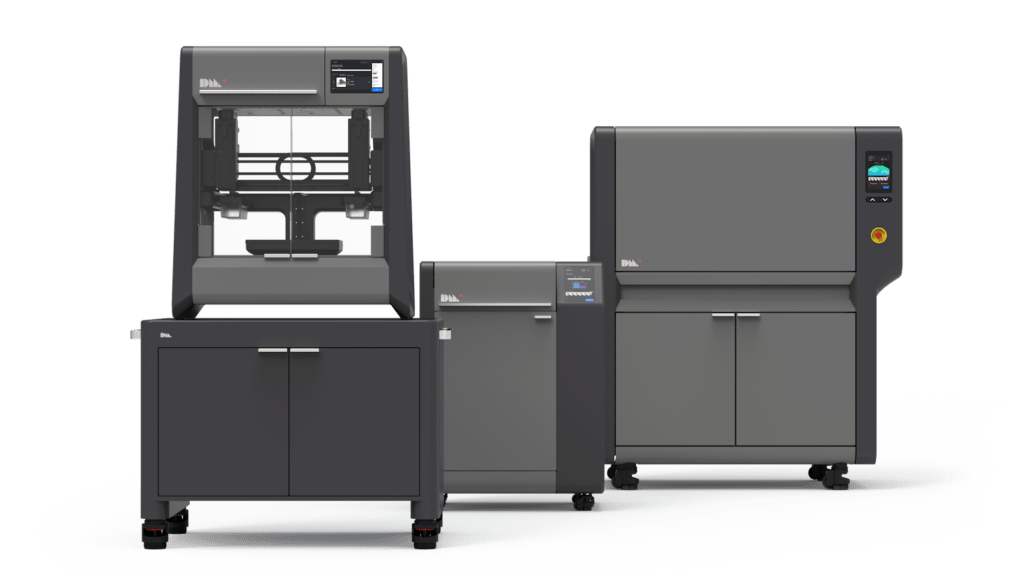

Studio System

The Studio System eliminates lasers and loose powders that make it safe for any facility, and there is no 3rd party equipment needed! This system is a 3-part solution that includes the printer, debbinder, and furnace that delivers printed parts from digital file to sintered part. The printer extrudes bound metal rods, and debbinder prepares green parts for sintering by dissolving primary binder, and the furnace is a fully-automated and delivers industrial-strength sintering.

MORE INFO »

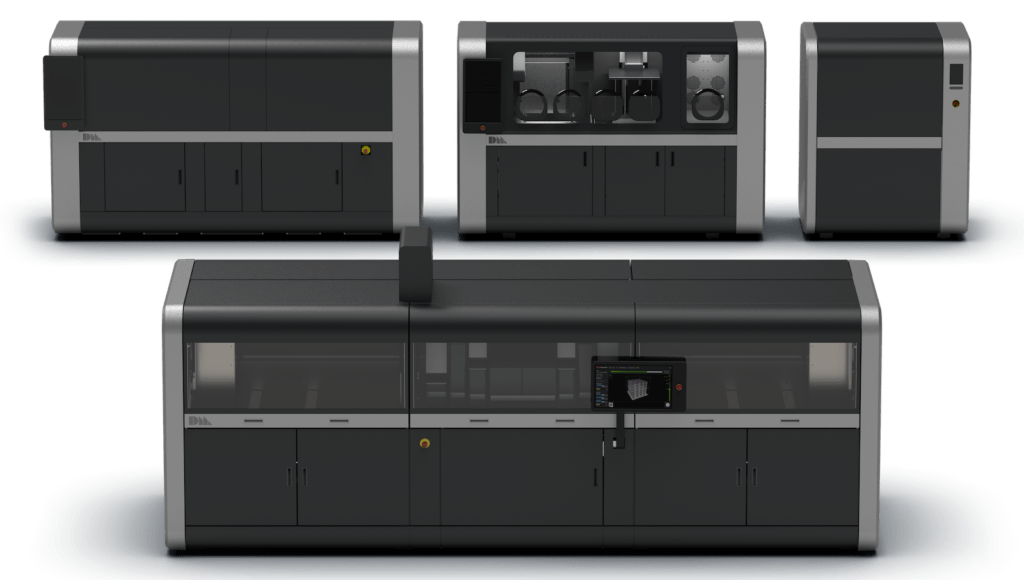

Production System

The Production System is a Metal 3D printing for mass production that delivers the speed, quality and cost-per-part needed. It is the fastest way to print metal parts at scale by using a breakthrough Single Pass Jetting 100x faster than quad-laser metal printers and 4x faster than the closest binder jetting alternative at a 20x lower cost-per-part.

MORE INFO »

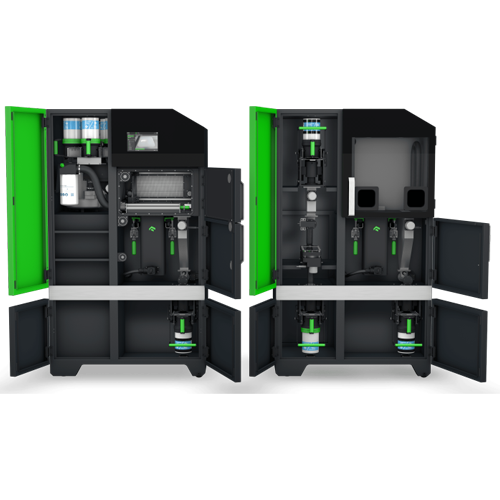

One Click Metal

One Click Metal

One Click Metal is leading the charge to reduce the complexity and cost of metal additive manufacturing technology, making it accessible to manufacturers large and small.

Stratasys

Stratasys

Stratasys develops industrial grade additive solutions to help you solve critical design and manufacturing challenges, right along your production cycle. Working with you to push the boundaries of what’s possible. And thrive in a changing world.

The range of 3D printers by Stratasys includes a wide range of solutions for Industrial, Commercial and Professional applications.

FDM®

Fused Deposition Modeling - FDM 3D Printers use thermoplastics, suitable for cost-effective prototyping and applications to produce quality parts for any industry. FDM technology is office-friendly, and delivers the necessary properties for applications that demand precise tolerances, durability, and stability.

MORE INFO »

P3 DLP

An evolution of digital light processing (DLP®), Programmable Photopolymerization technology (P3™) powers the Origin One. The tightly synchronized print process includes pneumatic controls to reduce pull forces during the print process, resulting in exceptional surface quality, without sacrificing speed or isotropy.

MORE INFO »