Index Corporation

CNC Turning Machines

INDEX is one of the world's leading providers of CNC turning machines. Via the INDEX and TRAUB brands, the company offers standard-setting Swiss, production, multi-tasking and multi-spindle CNC machines that perform multiple high precision operations in a single setup with rapid changeover and zero handling.

Production Turning Machines

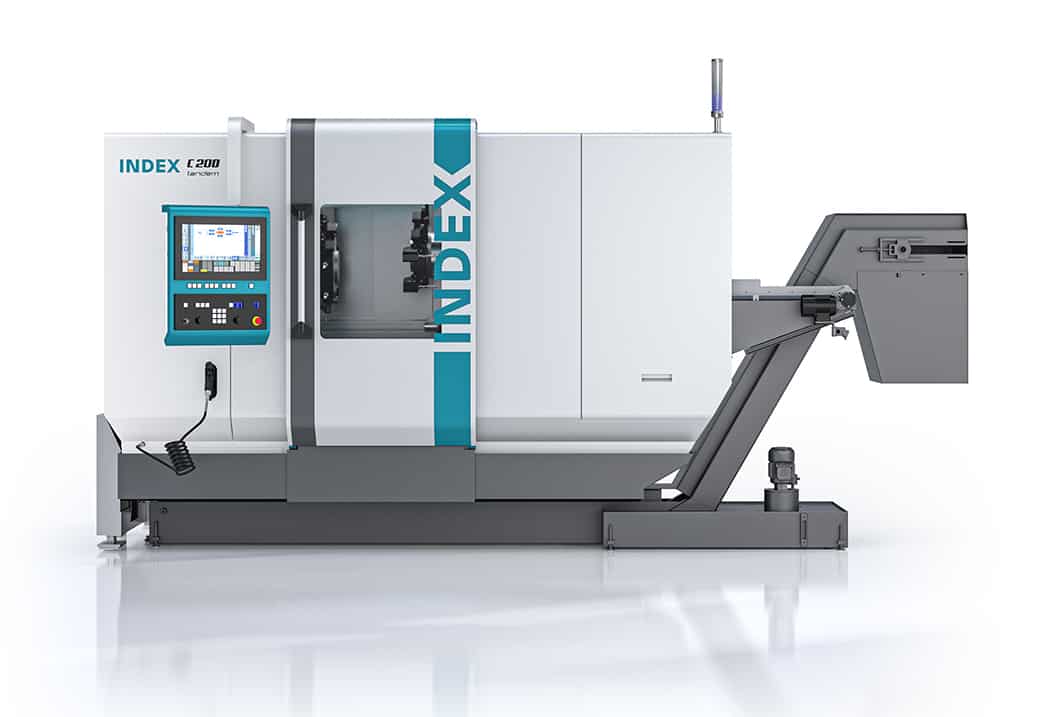

C200 Production Turning

Ideal for bar stock machining and complex workpieces, the C200 is a turning machine that has a generous work area for complete machining workpieces, and the INDEX SingleSlide guide system ensures a significantly faster dynamic response. Like the C100, the C200 is also built into a compact design and can act as a 2 or 3-turret-machine.

MORE INFO »

C100 Production Turning

Ideal for bar stock machining and complex workpieces, the C100 has the ability for simultaneous machining using 2 or 3 turrets, a 42mm spindle clearance, 110mm chuck diameter, 400mm turning length with, and high acceleration and high rapid traverses all in a compact design

MORE INFO »

Multi-Spindle Automatic Machines

MS16-6 /Plus Multi-Spindle Automatic Lathe

The MS16-6 / MS16-6 Plus is a dynamic multi-spindle automatic lathe with a 16/22mm bar diameter and 10,000 rpm max. speed with the shortest possible changeovers, and lowest secondary times. With a maximum of 12 tool carriers with 1 or 2 travel axes and a fast synchronous spindle for rear-end machining and the C-axis machining possible in every spindle position.

MORE INFO »

MS22-8 Multi-Spindle Automatic

The MS22-8 is a productive multi-spindle machine with 8 spindles, up to 2 swiveling synchronous spindles, up to 22(24)mm bar diameter, and up to 16 tool carriers. Anything is possible for the MS22-8 because it is an extremely versatile machine with highly-dynamic slides with sliding guide (X-axis) and a non-wearing Z-axis due to quills with hydrostatic support. There are more rear-end machining options with hydraulically locked and extremely fast swiveling synchronous spindle

MORE INFO »

MS40-6 Multi-Spindle Automatic

The MS40-6 is a multi-spindle machine that meets every demand in machining processes. The machine opens at the front for bar machining, and the swing arm is locked by a three-piece Hirth coupling for maximum rigidity. With different configurations, you can have a dual 3-spindle machine for 2 workpieces, or a 6 spindle machine with simultaneous reverse-side machine in two spindle positions for front end machining on 4 main spindles and simultaneous cutoff-side machining on 2 swiveling synchronous spindles.

MORE INFO »

MS52-6 Multi-Spindle Automatic

The MS52-6 is a multi-spindle automatic for rear-end machining. Perfect for milling, gear cutting/hobbing, and elliptical deburring applications. It can also be set up with a robot to add automation to your applications. Highlights for the machines include a highly-dynamic slide with sliding guide (x-axis), non-wearing Z-axis due to quills with hydrostatic support, and a maximum of 6 tools for rear end machining per swiveling synchronous spindle. 52mm bar diameter, 5,000 rpm max speed, 30 kW max power, and 130 Nm max. torque.

MORE INFO »

MS22-6 Multi-Spindle Automatic

The MS22-6 is a front open multi-spindle machine for a maximum 20 (24)mm bar diameter turned parts built for precision, speed, and flexibility. Extremely user-friendly, freely accessible, and highly dynamic slides with sliding guide (X-axis), and non-wearing Z-axis due to quills with hydrostatic support. Can be used for gear cutting, hobbing, milling, elliptical deburring of cross-drill holes.

MORE INFO »

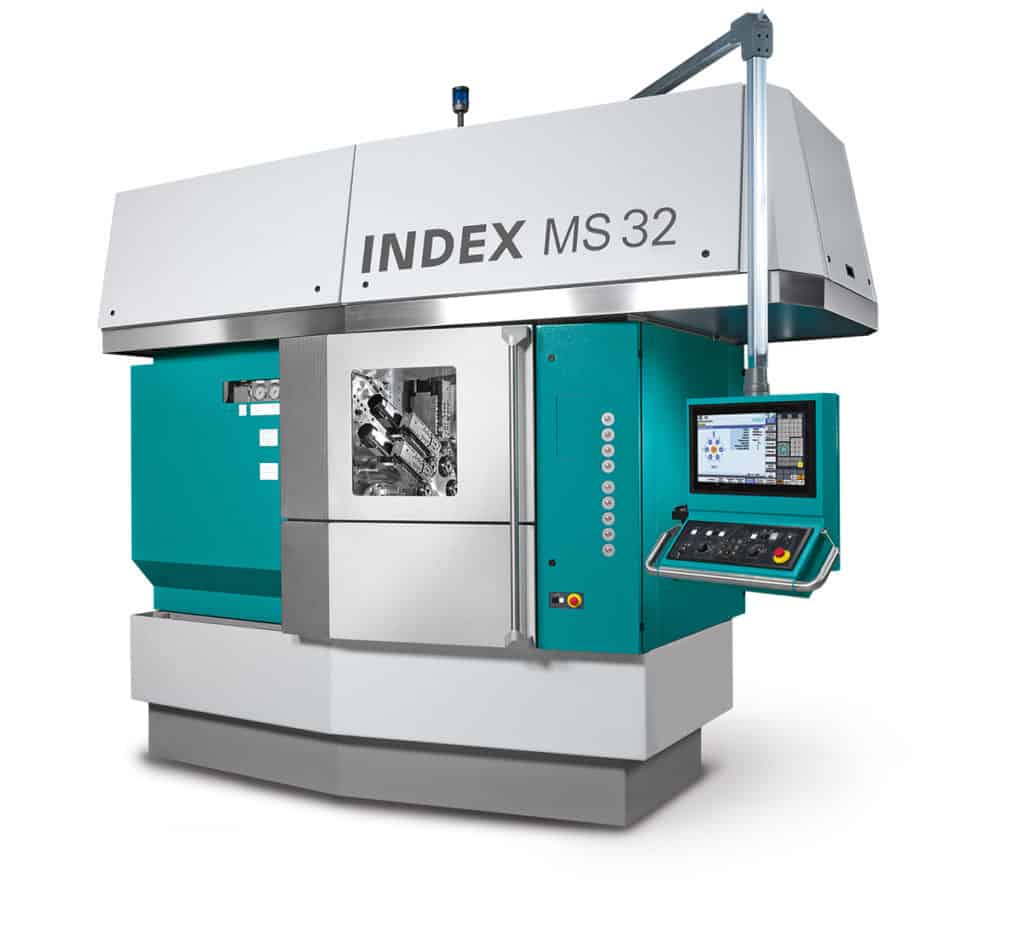

MS32-6 Multi-Spindle Automatic Lathe

The MS32-6 is a multi-spindle automatic lathe that is designed for high productivity and short cycle and set-up times. With up to a 32mm bar diameter, this machine comes with highly dynamic slideways on the X-axis, non-wearing Z-axis due to quills and hydrostatic support, a grooving and boring slide for maximum cutting performance, front-opening machine for bar stock machining, chuck part machining with robot loading and unloading, and up to 6 tools for rear end machining per swiveling synchronous spindle

MORE INFO »

MS40-8 Multi-Spindle Automatic

The MS40-8 is a multi-spindle automatic with 8 spindles perfect for applications with valve screws, driveshafts, and valves. This highly versatile machine can be configured at full extension to reduce cycle times by using the 8 working spindles, or a double 4 spindle for additional cycle time reduction for simultaneous machining of two workpieces. This MS40-8 has many highlights including a dynamic slide with sliding guide (x-axis), non-wearing Z-axis due to quills, front-opening machine, and a swing arm that is locked in by a 3-piece Hirth couple to for rigidity. 40 mm bar diameter, 7,000 rpm max speed, 24 kW max power, 57 Nm max. torque.

MORE INFO »

Turn-Mill Centers

G200 Turn-Mill Center

The G200 is a flexible turn-mill Center with 65mm spindle clearance, 165mm chuck diameter, and 660mm turning length. With the ability for a wide variety of machining options including - machining with up to four tools at the same time, machining of long workpieces without interruptions with turret 2 of turret 3 in parking position, and simultaneous internal machining on main and counter spindles, the G200 is great for your applications. The G200 has a large work area built into a compact footprint and allows a quick set-up for complete machining of bar stock.

MORE INFO »

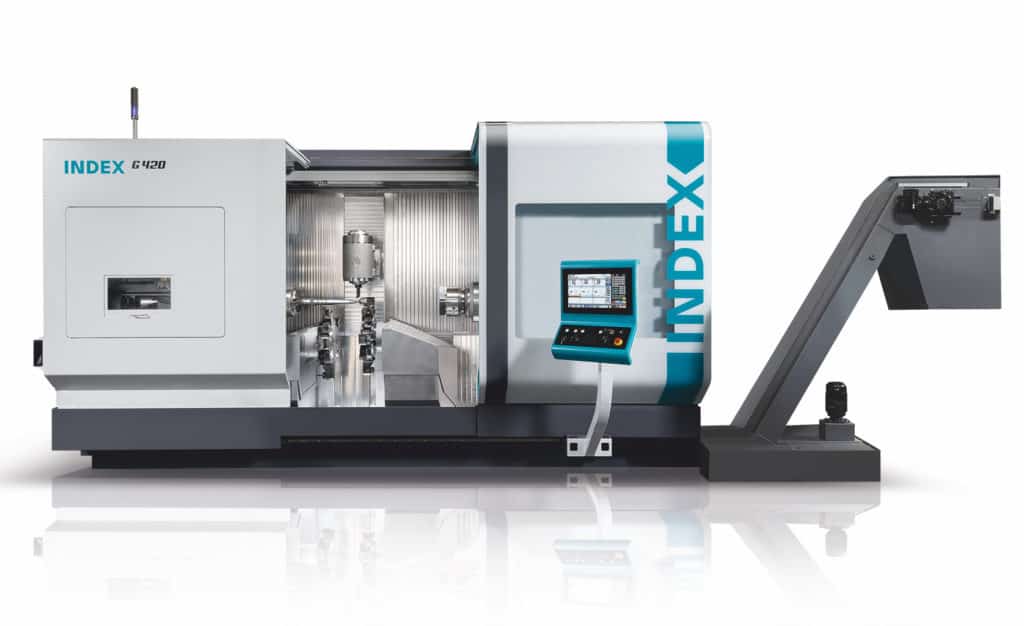

G400/G420 Turn-Mill Center

The G400/G420 is an innovative turn-mill center for high performance of large workpieces. This machine has an identical main and counter spindle clearance of 102 mm / 120mm, a chuck diameter of 315mm / 400mm, and turning length of 1600mm for different machining options. With the ability for tool stock up to 139 tools this G400/ G420 can be used in applications in the automotive, aerospace, and mechanical engineering industries. Parts like a turret head, flange, shaft, or rotor carrier are examples of what can be made on these machines.

MORE INFO »

R300 Turn-Mill Center

The R300 is 5-axis turn-mill center that can change up to 140 tools with a 6 second chip-to-chip time to shorten secondary process times on both spindles. Both milling spindles allow for simultaneous and independent loading. This machine can be set-up with a lot of automation options that can fit your manufacturing needs. The R300 is perfect for machining bevel gears. The powerful motorized milling spindle minimizes vibration and keeps your tools going longer.

MORE INFO »

G220 Turn-Mill Center

The G220 is a powerful turn-mill center that has a large work area for your applications, and a 6-sec chip-to-chip time with its 2 identical dynamic motorized milling spindle with 70 or 140 magazine stations. The G220 has a 65 (90) mm spindle clearance, 210mm chuck diameter, and 1,000 mm turning length, and allows for a fast tool change on its lower 18 or 12 tool stations. Simultaneous machining is possible with two tool carriers.

MORE INFO »

R200 Turn-Mill Center

The R200 is turn-mill center that will increase your productivity with its two independent subsystems and full 5-axis capability. With 12 stationary turning tools allowing for high rigidity and excellent cutting performance, and a motorized milling spindle with 18,000 RPM, this machine can handle a high cutting volume with short cycle times - chip-to-chip time of 4 seconds.

MORE INFO »

Sliding Headstock Automatic Lathes

TNL12 Sliding Headstock Lathe

The TNL12 is a sliding headstock automatic lathe with 13 (16 opt) mm spindle clearance, 12,000 rpm max speed, and 135 mm max Z-travel. Capable of simultaneous and independent machining, using up to 4 tool carriers in one clamping. The work area is accessible on both sides and has hydraulic hollow clamping cylinders for the main and counter spindles. The guide bushings can be fixed, following, or programmable. The machine is equipped with 6 stations, a 0.3 second chip-to-chip time, y-axis for lower tool turret, a separate z-axis for upper tool turret, and front and back working capabilities.

MORE INFO »

TNL32 Sliding Headstock Automatic Lathe

The TNL32 is a slight headstock automatic lathe with 32mm spindle clearance, 8,000 rpm max speed, and 305mm max Z-travel. Capable of simultaneous machine with up to 3 tools, large axis travels, wide toolng circles, easily accessible work area, easily switch between sliding and fixed headstock, and equipped with DualDrive. There are three version available for the TNL32 - equipped with a B-axis, Counter spindle for more flexibility, and a front working attachment for productivity.

MORE INFO »

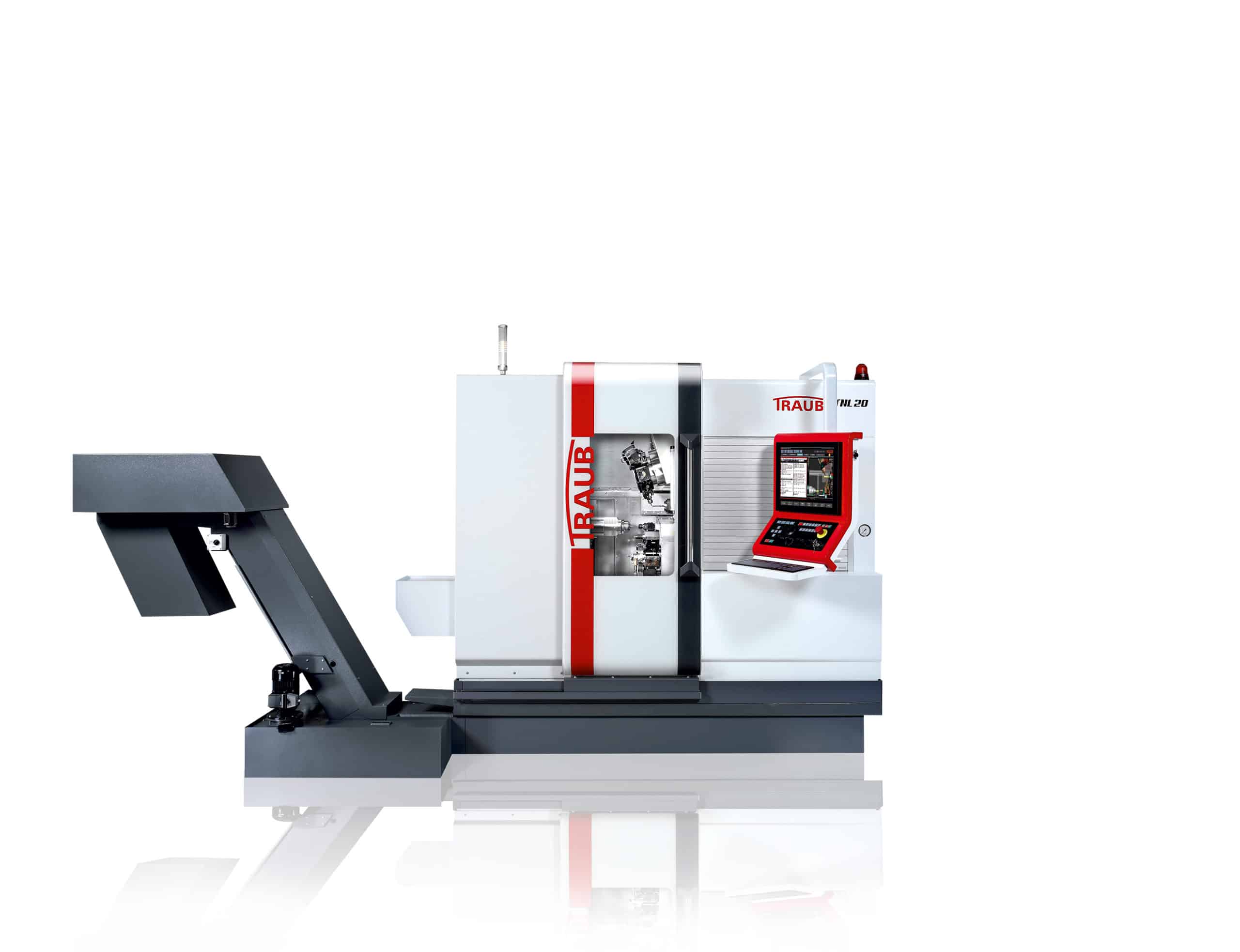

TNL20 Sliding Headstock Automatic Lathe

The TNL20 is a high performance sliding headstock automatic lathe with 20mm spindle clearance, 10,000 rpm max speed, and 205mm max Z-travel. Designed for sliding or fixed headstock turning for medium and high complexity workpieces from barstock, or easily integrated with a robot cell. Capable of simultaneous machining with 2, 3 or 4 tools, easy set-up with a high tool pool,quick tool change times, and a spacious work area.

MORE INFO »

MS22-6L Sliding Headstock Automatic Lathe

The MS22-6L, a multi-spindle automatic lathe with swiss type function, is perfect for high productivity machining of long parts. With 6 precise motorized spindles, bar clearance from 5mm - 22mm, and a workpiece length up to 200 mm the MS22-6L offers a wide range of machining possibilities. The integrated swiveling synchronized spindle allows rear end machining for damage-free placing of finished parts onto a parts conveyor. Perfect for your driveshaft, shaft, and control slide parts.

MORE INFO »

Vertical Turning Center

V160 Vertical Turning Center

The V160 is a Vertical Turning Center that increases productivity and flexibility. With a 65 mm spindle diameter, 160 (200) mm chuck diameter, and a 5,000 rpm max speed, the V160 has a flexible tool clamping plate for specialized machining methods, easy part supply with its balcony design, and allows for short secondary processing times from the linear motor in the X-axis.

MORE INFO »