Hyundai WIA

Machining Centers

From small-footprint vertical and horizontal machining centers and turning centers to rugged, large work area multitasking machines like those used in Hyundai Motors factories around the globe, Hyundai WIA Machine Tool offers a high-quality lineup of more than 100 different CNC machines to U.S. manufacturers.

Hyundai Wia CNC Turning Center Lathes

Compact Turning Center Lathes

KIT4500 Compact Turning Center Lathe

A compact turning center designed to maximize your productivity with it's 60° slanted one-piece rigid bed, and the ability to produce highly precise parts with reduced thermal displacement. Built-in a compact design the KIT4500 can fit in virtually any shop.

- Max turning diameter - 6.5"

- Max turning length - 11.8"

- Chuck Size - 6"

- Spindle Speed - 6,000 rpm

MORE INFO »

E160C Compact Turning Center Lathe

An affordable compact lathe designed to maximize your productivity with it's 45° slanted one-piece rigid bed structure. Equipped with a reliable high-speed servo turret at 0.1 sec/step, and a rapid travel speed of 30m/min. Built-in a compact footprint, and the chucks are easily accessible.

- Max turning Diameter - 11" C

- Max Turning Length - 11" C

- Chuck Size - 8"

- Spindle Speed - 4,000 rpm

MORE INFO »

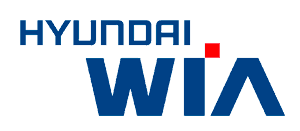

E160A Compact Turning Center Lathe

An affordable compact turning center designed to maximize your productivity with t's 45° slanted one-piece rigid bed structure and minimal heat distortion. Equipped with the most reliable high-speed servo turret at 0.1 sec/step, and best in its class rapid traverse rate of 30m/min. Build in a compact footprint, and the chucks and tools are easily accessible.

- Max turning Diameter - 11" A

- Max Turning Length - 11.8" A

- Chuck Size - 6"

- Spindle Speed - 6,000 rpm

MORE INFO »

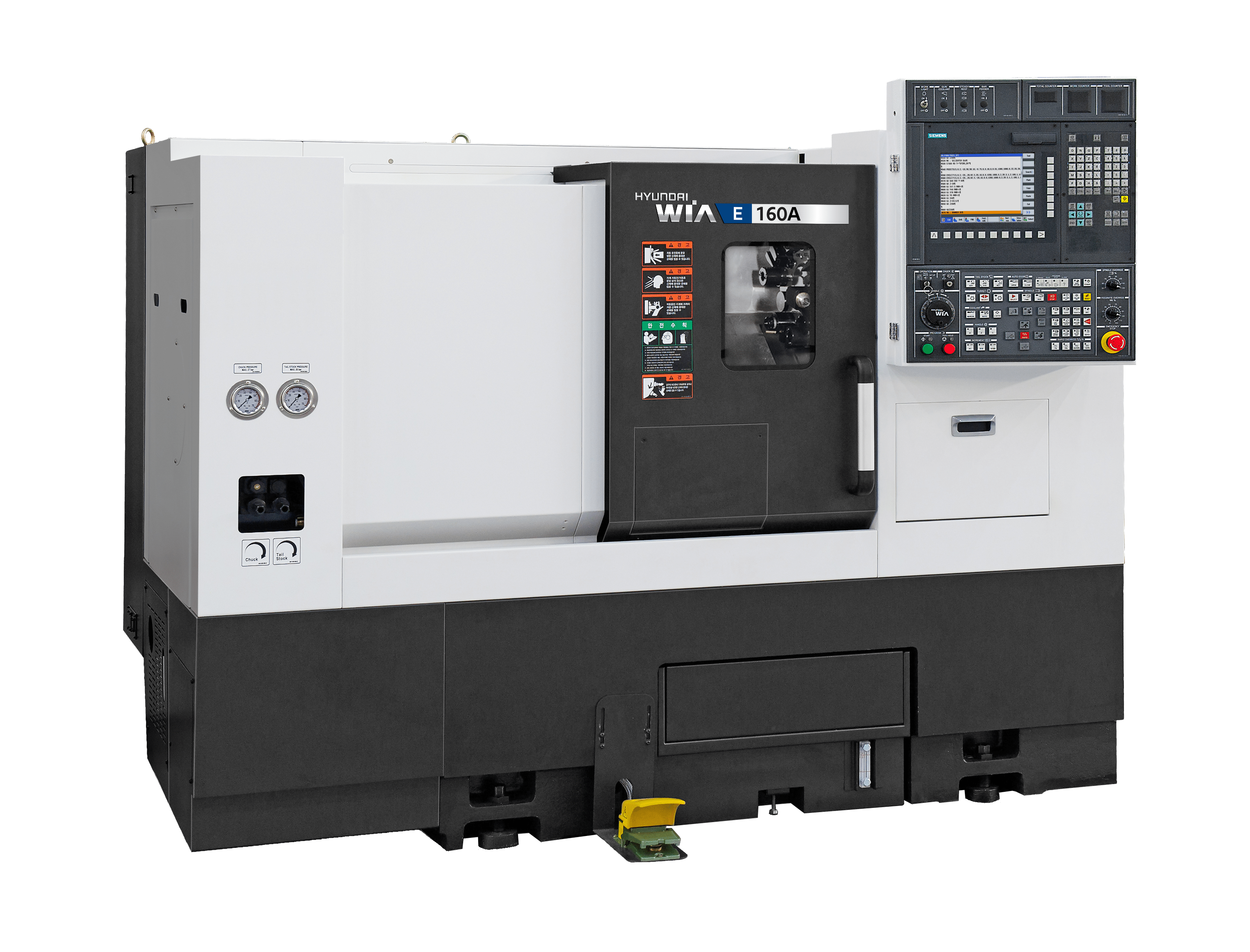

SE2200A/LA/MA/LMA Compact Turning Center Lathe

SE2200A | SE2200LA |SE2200MA | SE2200LMA

A compact lathe designed to maximize your productivity at an affordable price with it's 45° slanted one-piece rigid bed, and the ability to produce highly precise parts built in a compact design. Equipped with a rapid traverse rate of 36m/min (SE2000A/MA), box guideways to handle heavy-duty cutting (SE2000PA), and a reliable high-speed servo turret.

- Max Turning Diameter - 13.8" A, 11.4" MA, 13.8" PA

- Max Turning Length - 11.8" A, 10" MA, 11" PA

- Chuck Size - 6"

- Spindle Speed - 6,000 rpm

MORE INFO »

High Performance Turning Center Lathes

HD2600 High Performance Lathe

HD2600 | HD2600LE | HD2600M | HD2600LME

The HD2600 Series was designed for high speed, productive, rigid machining with a stable structure to minimize thermal displacement, and box guideways to perform heavy-duty cutting. With a user-friendly design, the HD2600 Series allows for easy access to chuck and tools to improve productivity and efficiency.

- Max Turning Diameter - 18.1", 19.7" LE, 15" M, 16.5" LME

- Max Turning Length 25.9", 30.7" LE, 24.1" M, 29.1" LME

- Chuck Size -10"

- Spindle Speed - 3,500 rpm

MORE INFO »

HD3100 High Performance Lathe

HD3100 | HD3100L | HD3100M | HD3100LM

The HD3100 Series was designed for high speed, productive, rigid machining with a stable structure to minimize thermal displacement, and box guideways to perform heavy-duty cutting. With it a user-friendly design, the HD3100 series allows for easy access to chuck and tools to improve productivity and efficiency.

- Max Turning Diameter- 19.7" L 16.5" M/LM

- Max Turning Length - 30.7", 51.2" L, 29.1" M, 49.6" LM

- Chuck Size - 12"

- Spindle Speed - 2,800 rpm

MORE INFO »

L300A/MA/MSA High Performance Lathe

L300A/MA/MSA is designed for heavy-duty cutting with highly rigid box guideways, a direct-drive spindle, and pretensioned double-anchored ballscrews for superior positioning and accuracy. Milling models (MA/MSA) equipped with a belt-driven spindle, and an optional 8" sub-spindle (MSA).

- Max Turning Diameter - 19.7", 16.1" MA/MSA

- Max Turning Length - 28.3", 26.8" MA/MSA

- Chuck Size - 10" A/MA

- Sub 8" MSA

- Spindle Speed - 3,600 rpm A, 3,500 rpm MA/MSA

- Milling Tool Speed - 4,000 rpm MA/MSA

MORE INFO »

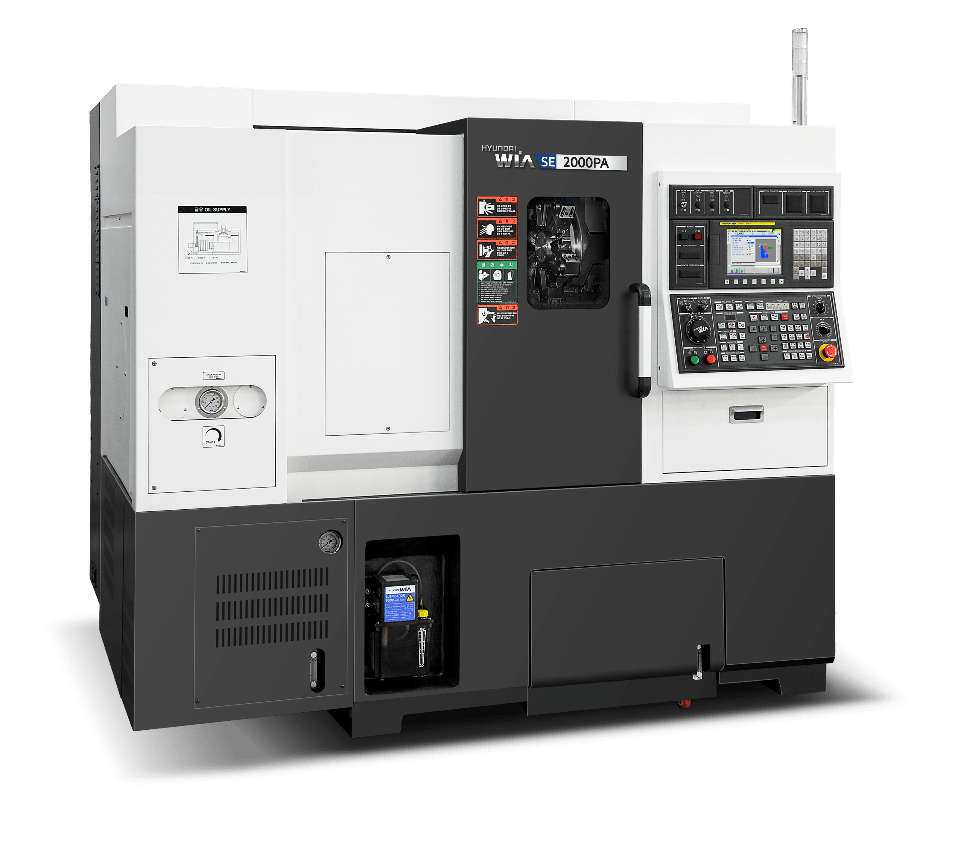

L700 High Performance Lathe

L700A | L700MA | L700LA | L700LA

The L700 Series are heavy-duty, large work capacity turning center lathes for powerful cutting and a wide machining area designed to machine long shafts and pipes up to 128". Built with large box guideways on all axes for high rigidity, all-in-one structure, pretensioned double anchored ballscrews for superior positioning and accuracy, and a 3-step gearbox driven spindle.

- Max Turning Diameter - 36.2"

- Max Turning Length - 65" A/MA, 128" LA/LMA

- Chuck Size - 24"

- Spindle Speed - 1,500 rpm

- Milling Tool Speed - 3,000 rpm MA/LMA

MORE INFO »

HD2200 Series High Performance Lathe

HD2200 | HD2200C | HD2200M | HD2200MC

The HD2200 Series is designed for high speed, rigidity, and productivity. The 45 degree slanted one-piece bed and box guideways are built for rigid, heavy-duty cutting. This 8" (10" C/MC) lathe built in a compact design with easy access to chuck and tool to maintain productivity, and a high-speed servo turret 0.12sec/step.

- Maximum Turning Diameter - 15" C, 11.8" M/MC

- Max Turning Length - 22.2", 21.7" C, 18.4" M, 17.8" MC

- Chuck Size- 8" M, 10" C/MC

- Spindle Speed - 4,000 rpm M, 3,500 rpm C/MC

MORE INFO »

L300MC/LMC/MSC High Performance Lathe

The L300MC/LMC/MSC series is designed for milling, heavy-duty cutting, a sturdy all axis box guide, pretension double anchored ball screw for superior positioning and accuracy, and a belt-type spindle. There is also a big bore option.

- Max Turning Diameter - 19.7"

- Max Turning Length - 23.6" MC, 49.6" LMC, 23.6" MSC

- Chuck Size - 12" MC/LMC

- Sub 8" MSC

- Spindle Speed - 3,000 rpm

- Milling Tool Speed - 4,000 rpm

MORE INFO »

L600 High Performance Lathe

L600A | L600MA | L600LA | L600LMA

The L600 Series are heavy-duty, large work capacity turning center lathe for powerful cutting and a wide machining area designed to machine long shafts and pipes up to 128". Built with large box guideways on all axes for high rigidity, all-in-one structure, pretensioned double anchored ballscrews for superior positioning and accuracy, and 3-step gearbox driven spindle.

- Max Turning Diameter - 36.2"

- Max Turning Length - 65" A/MA, 128" LA/LMA

- Chuck Size - 18"

- Spindle Speed - 1,800 rpm

- Milling Tool Speed -3,000 rpm MA/LMA

MORE INFO »

Front Loading Turning Centers

Vertical Turning Centers

LV500 Vertical Turning Center

LV500R/L | LV500RM/LM

The LV500 Series is a high-performance Vertical Turning center that features a box-type column that offers stability by absorbing vibration. Available in a milling configuration as well. Designed with a 2-step chuck pressure mechanism to minimize material deformation, and an all-in-one machine structure, and a "right" and "left" option for an easy automation setup.

- Max Turning Diameter - 21.7"

- Max Turning Length - 23.6"

- Chuck Size - 15"

- Spindle Speed - 2,000 rpm

- Milling Tool Speed - 3,000 rpm LV500RM/LM

MORE INFO »

LV1100 Vertical Turning Center

LV1100R/L | LV1100RM/LM

The LV1100 Series is a vertical turning center that was designed for prolonged high speed, accurate, heavy-duty cutting with tight tolerances and eliminates the need for separate finishing or grinding operations. Designed with a 2-step chuck pressure mechanism to minimize material deformation, an all-in-one machine structure, and a "right" and "left" options for an easy automation set-up.

- Max Turning Diameter - 45.7"

- Max Turning Length - 39.4"

- Chuck Size -32"

- Spindle Speed - 800 rpm

- Milling Tool Speed - 3,000 rpm LV1100RM/LM

MORE INFO »

LV2000MM Vertical Turning Center

The LV2000MM is a high performance, heavy-duty vertical turning center capable of turning, tapping, milling, grinding, etc. Designed with a highly rigid table structure for heavy load capacity, a main spindle and box guideways on all axes for longevity for heavy-duty applications, and a heavy-duty 2-step geared drive.

- Max Turning Diameter - 78.7"

- Max Turning Length - 66.9"

- Chuck Size - 63"

- Spindle Speed - 258 rpm

- Milling Tool Speed - 2,400 rpm

MORE INFO »

LV800 Vertical Turning Center

LV800R/L | LV800RM/LM

The LV800 Series is a high-performance vertical turning center that features a box-type column that offers stability by absorbing vibration. Available in a milling configuration, and a high torque spindle for a 24" chuck as well. Designed with a 2-step chuck pressure mechanism, adopted to minimize material deformation, an all-in-one machine structure, and a "right" and "left" option for an easy automation set-up.

- Max Turning Diameter - 31.5"

- Max Turning Length - 31.5"

- Chuck Size - 18"

- Spindle Speed - 2,000 rpm

- Milling Tool Speed - 3,000 rpm LV800RM/LM

MORE INFO »

LV1400 Vertical Turning Center

The LV1400 is a high performance, heavy-duty vertical turning center for large-sized workpieces perfect for Energy and Plant Equipment Industry. Extra strength heavy-duty cutting is possible with the two-step gear drive. The thermo-friendly design allows the machine to hold tight tolerances and eliminates the need for separate finishing and grinding operations. The main spindle is designed with cross rollers and box guides on all axes for rigidity.

- Max Turning Diameter - 55.1"

- Max Turning Length - 33.5"

- Chuck Size - 40"

- Spindle Speed - 492 rpm

MORE INFO »

Multi-Axis Turning Centers

L2000SY Series Multi-Axis Turning Center

L2000Y | L2000LY | L2000SY | L2000LSY

The L2000SY Series are multi-axis turning centers designed for multitasking and maximizing productivity. Equipped with a wedge type Y-axis BMT65P turret, box guideways that allow for heavy-duty cutting, and integrated processing through the main/sub-spindle.

- Max Turning Diameter - 16.54"

- Max Turning Length - 20.47" Y/SY

- Chuck Size - 8" Main 8" Sub 6" SY/LSY

- Spindle Speed - 5,000 rpm

- Milling Tool Speed - 5,000 rpm

MORE INFO »

L3000SY Multi-Axis Turning Center

L3000Y | L3000SY | L3000LY

The L3000SY Series are multi-tasking turning centers designed for multitasking and maximizing productivity. Equipped with a wedge type Y-axis BMT65P turret, box guideways that allow for heavy-duty cutting, and integrated processing through the main/sub-spindle.

- Max Turning Diameter - 16.54"

- Max Turning Length - 29.9"

- Chuck Size - Main 12", Sub 6" SY

- Spindle Speed - 3,000 rpm

- Milling Tool Speed - 5,000 rpm

MORE INFO »

HD-Y Multi-Axis Turning Center

HD2200Y | HD2600Y

The HD-Y Series is a multi-tasking y-axis turning center designed to maximize productivity. Equipped with a one-piece and 30 degree slanted bed assures high-rigidity in the structures, box guideways for enhanced cutting ability, and a wedge type Y-axis BMT55P turret for complex machining.

- Max Turning Diameter - 11.8"

- Max Turning Length - 25.6"

- Chuck Size - 8" HD2200Y, 10" HD2600Y

- Spindle Speed - 4,000 rpm HD2200Y, 3,500 rpm HD2600Y

- Milling Tool Speed - 6,000 rpm

MORE INFO »

SE-SY Series Multi-Axis Turning Center

SE2200LSY | SE2200LSYA

The SE-SY Series are versatile, high production Y-axis CNC turning centers that are great for a variety of applications. Equipped with a 30 degree slanted bed to absorb vibration and minimize thermal grouth, roller guide ways on the X, Y, and Z axis for improved rigidity, and a full contouring C-axis.

- Max Turning Diameter - 11.8"

- Max Turning Length - 20.1"

- Chuck Size - Main 8" Sub 5"

- Spindle Speed - 4,4500 rpm

- Milling Tool Speed - 6,000 rpm

MORE INFO »

L2600SY Multi-Axis Turning Center

L2600Y | L2600SY | L2600LY

The L2600SY Series are multi-axis turning centers designed for multitasking and maximizing productivity. Equipped with a wedge type Y-axis BMT65P turret, box guideways that allow for heavy-duty cutting, and integrated processing through the main/sub-spindle.

- Max Turning Diameter - 16.54"

- Max Turning Length - 29.9" and 50.4" LY

- Chuck Size - 10" Y/LY and Main 10" Sub 6" SY/LSY

- Spindle Speed - 5,000 rpm

- Milling Tooling Speed - 5,000 rpm

MORE INFO »

LM1800TT Multi-Axis Turning Center

LM1800TTS | LM1800TTMS | LM1800TTSY

The LM1800TT Series is a high production twin-spindle and mill turret CNC lathe that allows for cutting time reduced due to synchronous rotation control of the opposite-type main spindle. Equipped with a 45 degree slanted bed design to absorb vibration and minimizes thermal growth, the hybrid-type feed shaft combining the box and roller guides, and upper and lower turrets increase productivity.

- Max Turning Diameter - 9.1"

- Max Turning Length - 26.5"

- Chuck Size - Main 8" Sub 8"

- Spindle Speed - 5,000 rpm

- Milling Tool Speed - 5,000 rpm TTMS/TTSY

MORE INFO »

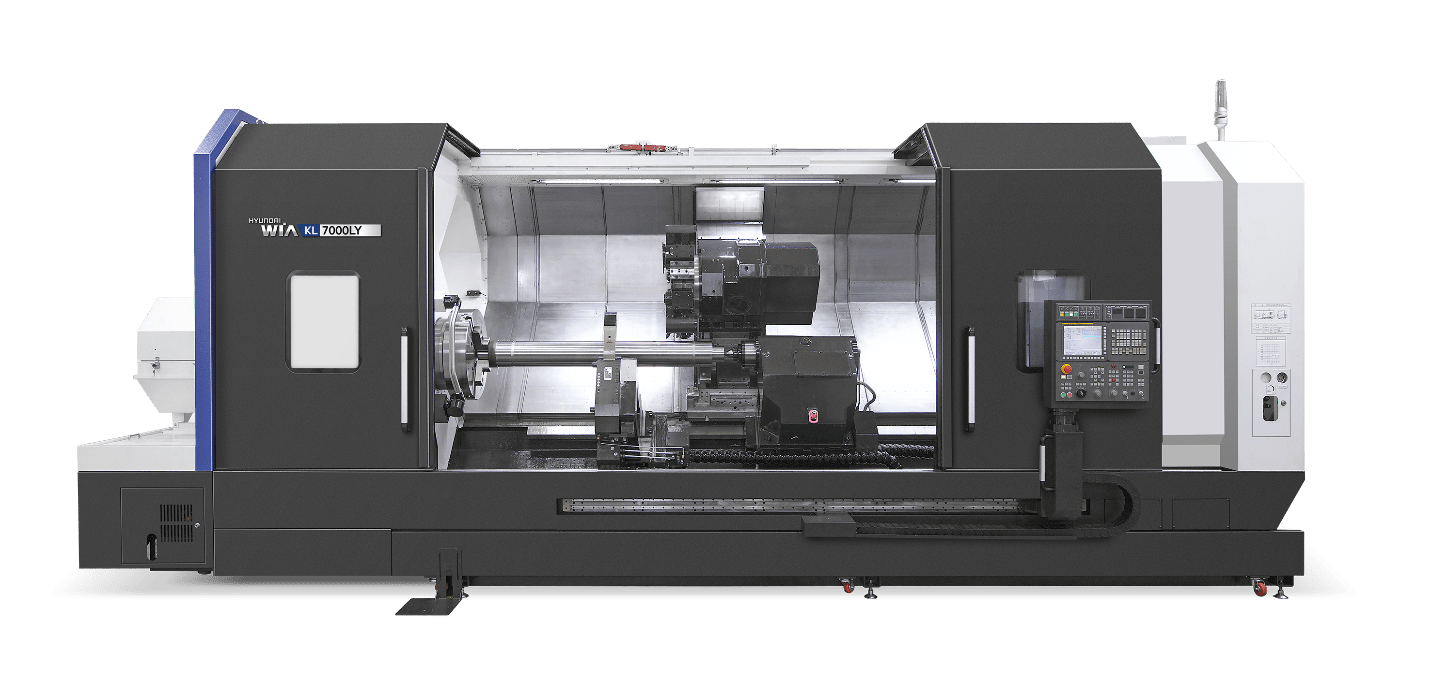

KL7000/8000LY Multi-Axis Turning Center

The KL7000/8000LY is a heavy-duty, large capacity turning center, and can be used for a variety of applications machining long shafts and pipes with a length of 128". Equipped with either a 3-step gearbox type main spindle (KL7000LY) or a 2-step gearbox type main spindle, and box guideways on all axis for rigidity.

- Max Turning Diameter - 36.2"

- Max turning Length - 128"

- Chuck Size - 24" KL7000LY, 32" KL8000LY

- Spindle Speed - 1,500 rpm KL7000LY, 700 rpm KL8000LY

- Milling Tool Speed - 3,000 rpm

MORE INFO »

Hyundai Wia Vertical Machining Centers

Tapping Center

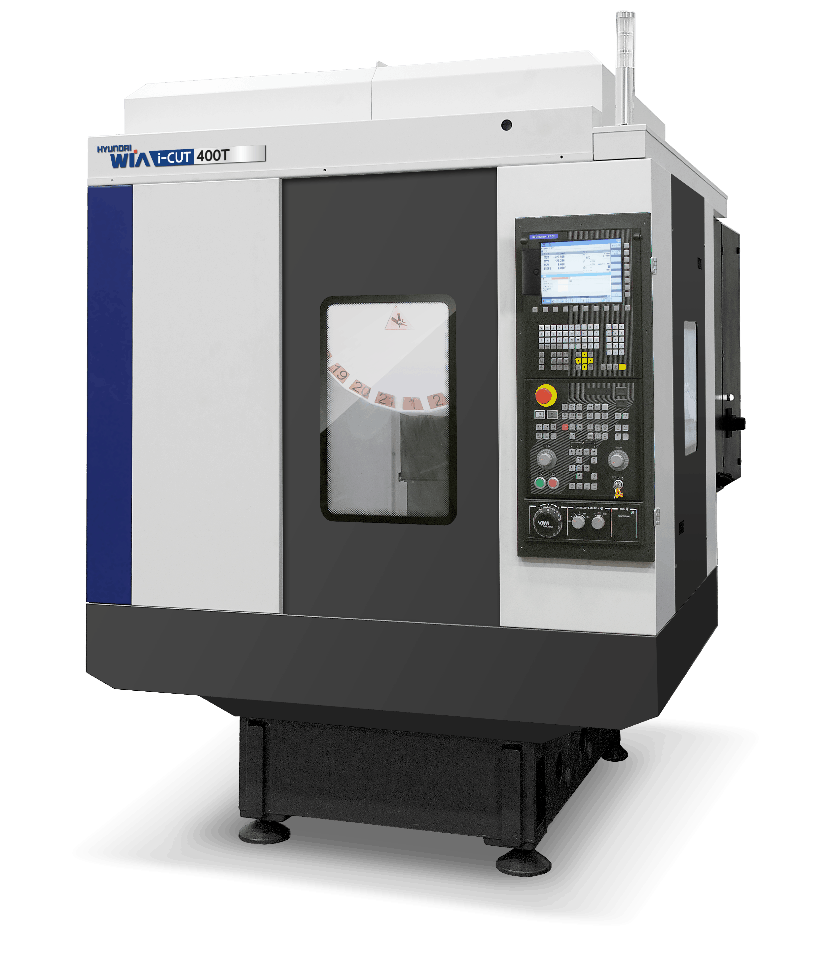

i-CUT400T/M Vertical Machining Center

i-CUT400T | i-CUT400M

Perfect for automotive, medical, and IT mass production parts, the i-CUT400 Series is a tapping center capable of high quality performance. Equipped with a high speed direct 12,000 rpm (i-CUT400T) or 24,000 rpm (i-CUT400M) BBT30 spindle, a spindle accel/decel of 1.6 seconds, rapid feed rate of 56m/min.

- Table Size - 25.6" x 15.7"

- Max Load Capacity - 661.4 lb

- Travel X/Y/Z - 19.7"/15.7"/13"

MORE INFO »

i-CUT400TD Vertical Machining Center

Perfect to efficiently produce automotive, medical, and IT mass production parts using its dual table system. Equipped with a high-speed direct connection BBT30 spindle with a max RPM of 15,000, and a chip to chip time of 1.74 seconds with the servo motor-driven ATC.

- Table Size - 2 - 25.6"x15.7"

- Max Load Capacity - 2 x 551 lbs

- Travel X/Y/Z -20.5"/15.7"/13"

MORE INFO »

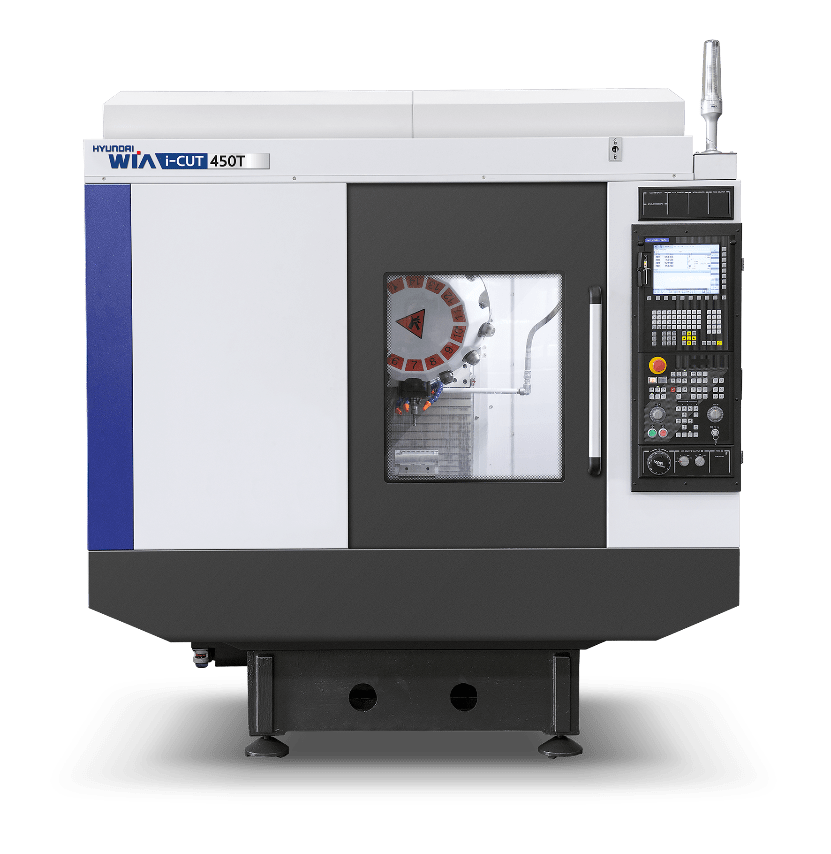

i-CUT450T Vertical Machining Center

Perfect for automotive, medical, and IT mass production for small and mid-size parts. Equipped with a high speed 15,000 max RPM direct connect BT30 spindle, servo motor-powered armless-type ATC, and a chip-to-chip time of 1.89 seconds.

- Table Size - 33.5" x 18.1"

- Max Load Capacity - 661 lbs

- Travel X/Y/Z - 27.6"/17.7"/13"

MORE INFO »

High Speed Machining Center

F400 High Speed Machining Center

F400 | F500PLUS | F500/50

Built for die/mold and medical machining because of its capabilities to machine complex, contoured geomtric parts, the F400/500 Series are productive and provide stiff and rigid heavy duty machining. Equipped with BBT40 (BT50 F500/50) spindle, with a 8,000 RPM spindle max, high power and high torque headstock that includes angular contact bearings for high precision.

- Table Size - 39.4" x 18.1" F400, 47.2" x 19.7" F500PLUS, 47.2" x 19.7" F500/50

- Max Load Capacity - 1,323 lbs F400, 50 1,764 lbs F500PLUS/F500

- Travel X/Y/Z - 31.5"/18.1"/20.5" F400, 41.7"/20.1"/25"F500PLUS, 43.3"/20.1"/25" F500/50

MORE INFO »

F650 High Speed Machining Center

Machines in F650 Series F650PLUS | F650/50 Designed for high-speed/hard-milling for die/mold and medical applications. Equipped with a highly accurate headstock, high torque headstock for precision in cutting, fast feeding through the 4 way Y-axis, front roller guideway for high accuracy cutting, and Servo ATC for quick tool exchange.

- Table Size - 63"x 25.6"

- Max Load Capacity - 2,866lbs

- Travel X/Y/Z - 55.1"/26"/25"

MORE INFO »

KF4600 High Speed Machining Center

The KF4600 Series is a high-speed VMC with a direct driven spindle (8,000/10,000/12,000 RPM) or an option of built-in spindle (15,000/20,000RPM). Large Y-axis for an increased machining area, the rapid feeds (36/36/36m/min) shorten non-cutting time, 30 Tool ATC, and a chip-to-chip time of 3.2 seconds

- Table Size - 41.3"x18.1"

- Max Load Capacity - 1,323 lbs

- Travel X/Y/Z - 35.4"/18.1"/20.5"

MORE INFO »

KF5600C High Speed Machining Center

A high-speed VMC similar to the KF5600, but with an expanded z-axis high column area of 635mm. A direct driven spindle up to 12,000 rpm. A large y-axis with a machining area of 560mm, rapid feeds to shorten non-cutting times (40/40/36m/min), 30 tool ATC, and a chip-to-chip time of 3.2 seconds.

- Table Size - 49.2"x22"

- Max Load Capacity - 2,205 lbs

- Travel X/Y/Z - 43.3"/22"/20.5"

MORE INFO »

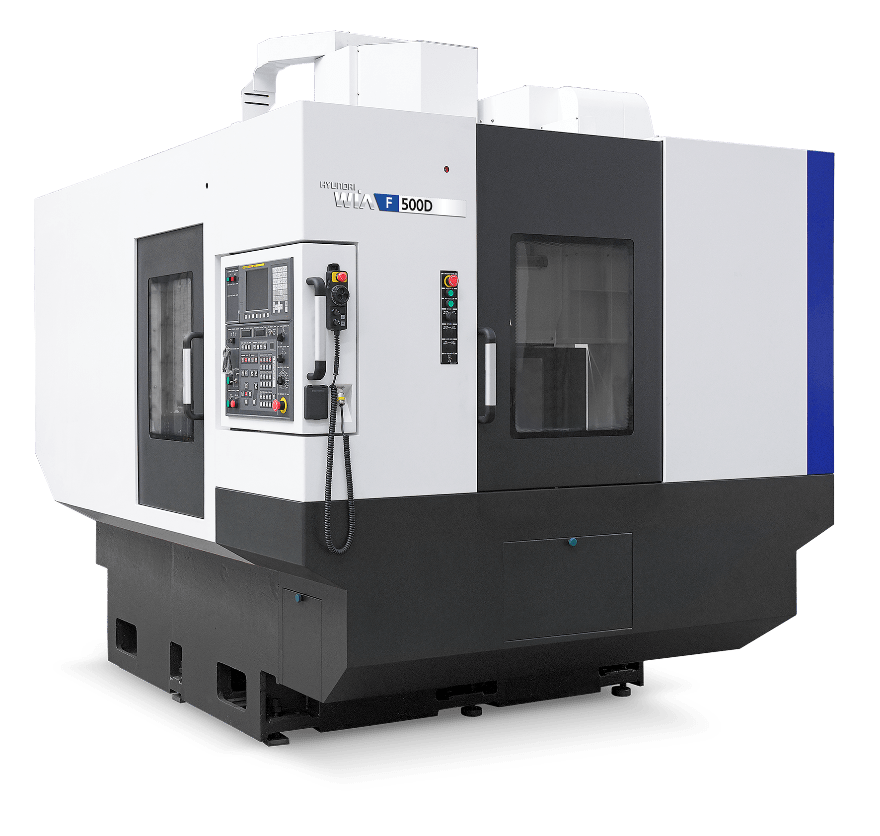

F500 High Speed Machining Center

F400 | F500PLUS | F500/50

Built for die/mold and medical machining because of its capabilities to machine complex, contoured geomtric parts, the F400/500 Series are productive and provide stiff and rigid heavy duty machining. Equipped with BBT40 (BT50 F500/50) spindle, with a 8,000 RPM spindle max, high power and high torque headstock that includes angular contact bearings for high precision.

- Table Size - 39.4" x 18.1" F400, 47.2" x 19.7" F500PLUS, 47.2" x 19.7" F500/50

- Max Load Capacity - 1,323 lbs F400, 1,764 lbs F500PLUS/F500/50

- Travel X/Y/Z - 31.5"/18.1"/20.5" F400, 41.7"/20.1"/25" F500PLUS, 43.3"/20.1"/25" F500/50

MORE INFO »

F850 High Speed Machining Center

A high-speed VMC designed to machine large aluminum metal plates and sheets. Equipped with an 850mm Y-axis with 4 guideways for smooth and rigid machining, a roller type LM guide that allows for a Ball Type Guide, and a high speed 24 Tool Twin Arm Automatic tool changer with a chip-to-chip time of 4.7 seconds.

- Table Size - 70.9"x33.5"

- Max Load Capacity - 2,204lbs

- Travel X/Y/Z - 63"/33.5"/22.8"

MORE INFO »

KF5600 High Speed Machining Center

A high-speed VMC with the options of a direct driven spindle (8,000rpm/12,000rpm) or a built-in spindle speed (15,000rpm/ 20,000 rpm). A large y-axis with a machining area of 560mm, rapid feeds to shorten non-cutting time (40/40/36m/min), 30 tool ATC, and a chip to chip time of 3.2 seconds.

- Table Size - 49.2"x 22"

- Max Load Capacity - 2,205lbs

- Travel X/Y/Z - 43.2"/22"/20.5"

MORE INFO »

KF6700 High Speed Machining Center

A high-speed VMC with the option of a direct-driven spindle (8,000/12,000rpm), or a built-in spindle (15,000/20,000 rpm). A large y-axis with a machining area of 670mm, a chip-to-chip time of 3.2 seconds, and perfect for mold machining.

- Table Size - 59"x26.4"

- Max Load Capacity - 2,866lbs

- Travel X/Y/Z - 51.2"/26.4"/25"

MORE INFO »

Heavy Duty Cutting

F510B Heavy-Duty Cutting

Designed for the die/mold and medical industries because of its ability to machine complex and contoured geometry, the F510B is a high precision VMC capable of heavy-duty cutting. Equipped with a gear-driven 8,000 rpm BT40 spindle, box guideways, and a Servo ATC technology to efficiently change tools.

- Table Size - 47.2" x 19.7"

- Max Load Capacity - 1,764 lbs

- Travel X/Y/Z - 43.3"/20.1"/25"

MORE INFO »

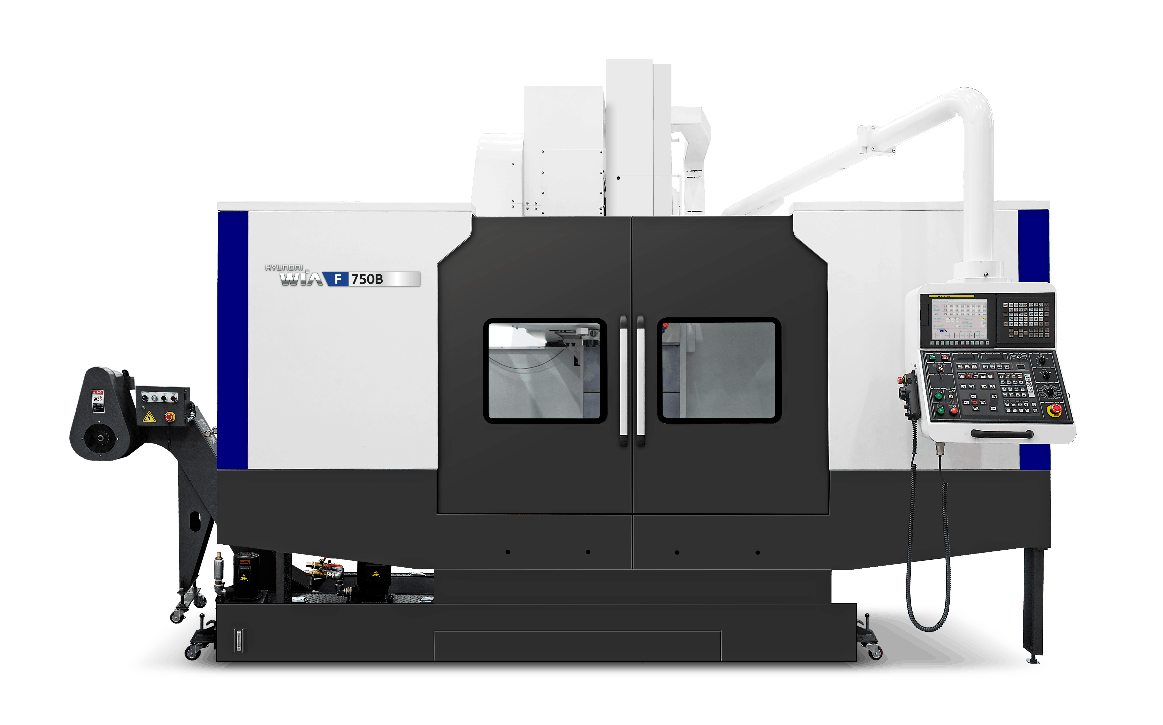

F750B Heavy-Duty Cutting

Designed for the die/mold and medical industries because of its ability to machine complex and contoured geometry, the F750B is a high precision VMC capable of heavy-duty cutting. Equipped with an extremely powerful 4,500 rpm gear-driven BBT50 spindle, pneumatic slideway for accurate positioning, and box guideways on all axes.

- Table Size - 70.9" x 27.6"

- Max Load Capacity - 4,409 lbs

- Travel X/Y/Z - 61"/29.5"/28.3"

MORE INFO »

KF6700B Heavy-Duty Cutting

A vertical machining center designed with box guideways for superior feeding during heavy-duty cutting. With a spindle speed up to 12,000rpm and a choice of a direct or gear driven high torque main spindle to handle the heavy-duty cutting. The machine is equipped with a Servo 30 (24 for KF6700B/50) tool ATC, and a chip-to-chip time of 3.5 seconds (5.5 seconds for KF6700B/50).

- Table Size - 59"x26.4"

- Max Load Capacity - 2,866lbs

- Travel X/Y/Z - 51.2"/26.4"/25"

MORE INFO »

KF7700B Heavy-Duty Cutting

A VMC designed with high rigidity and precision with the box guideways for superb heavy-duty cutting. With spindle speed up to 12,000rpm and a choice of a direct or gear-driven high-torque main spindle to handle the heavy-duty cutting. The machine is equipped with up to Servo 30 tool ATC, and a chip-to-chip time of 3.5 seconds.

- Table Size - 65"x30"

- Max Load Capacity - 3,307 lbs

- Travel X/Y/Z - 59"/30"/25"

MORE INFO »

F600B Heavy-Duty Cutting

Designed for the die/mold and medical industries because of its ability to machine complex and contoured geometry, the F600B is a high precision VMC capable of heavy-duty cutting. Equipped with a gear-driven 4,500 rpm BT50 spindle, box guideways, and a Servo ATC technology to efficiently change tools.

- Table Size - 63" x 23.6"

- Max Load Capacity - 2,205 lbs

- Travel X/Y/Z - 45.3"/23.6"/23.6"

MORE INFO »

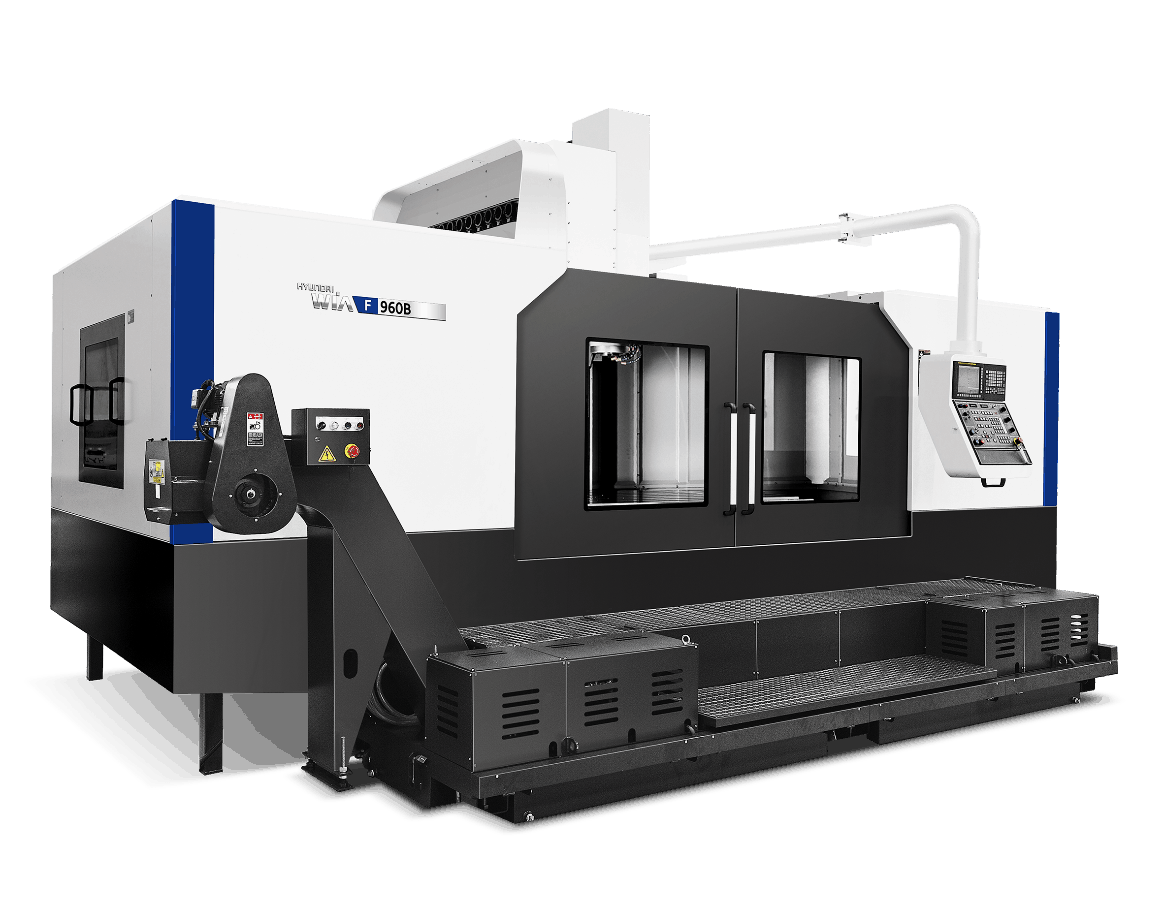

F960B Heavy-Duty Cutting

Designed for chatter-free, rigid cutting for high-speed hard-milling in die/mold, and medical applications. Equipped with an ultra-precise Cylindrical Roller Bearing on the main spindle, air semi-rising slideway, 4WAY 10 faces box guide design, box guideways on all axes, and an 8,000 rpm BBT50 gear driven spindle.

- Table Size - 106.3" x 37.4"

- Max Load Capacity - 9,921 lbs

- Travel X/Y/Z - 96.4"/37.8"/33.4"

MORE INFO »

KF5700B Heavy-Duty Cutting

A vertical machining center designed with box guideways for superior feeding during heavy-duty cutting. With a spindle speed up to 8,000rpm and a choice of a direct or gear-driven high-torque main spindle to handle the heavy-duty cutting. The machine is equipped with a Servo 30 (24 for KF5700B/50) tool ATC, and a chip-to-chip time of 3.5 seconds (5.5 seconds for KF5700B/50).

- Table Size - 51.2"x22.4"

- Max Load Capacity - 2,205lbs

- Travel X/Y/Z - 43.3"/22.4"/20.5"

MORE INFO »

Mold Machining

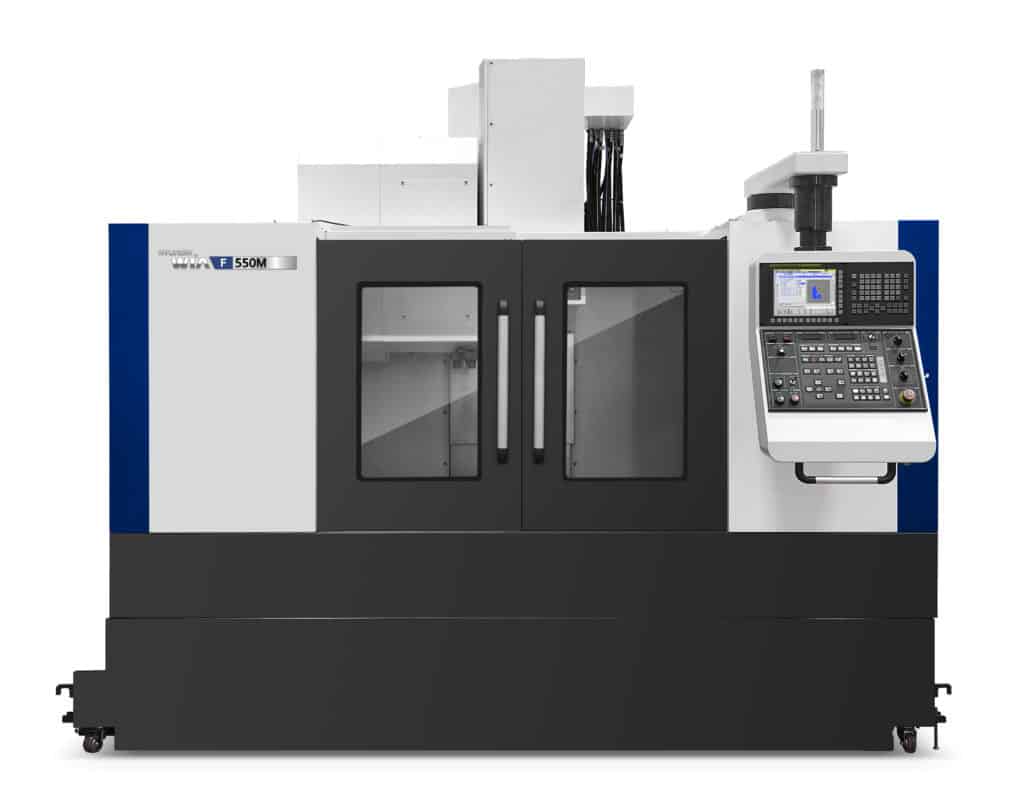

F550M/660M Mold Machining

F550M | F660M

Designed for high-speed mold machining with a built-in, highly precise 15,000rpm spindle and an optimal mold package. The semi servo ATC allows for the shortest tool change time of 3.61 seconds (F550M) and 3.9 seconds (F660M). The F660M is Equipped with a Y-axis with 4 guideways for ultra rigidity and smooth motion.

- Table Size - 47.2"x21.7"

- Max Load Capacity - 1,764lbs F550M, 2,866lbs F660M

- Travel X/Y/Z - 43.3"/21.7"/20.5" F550M, 55.1"/26"/25" F660M

MORE INFO »

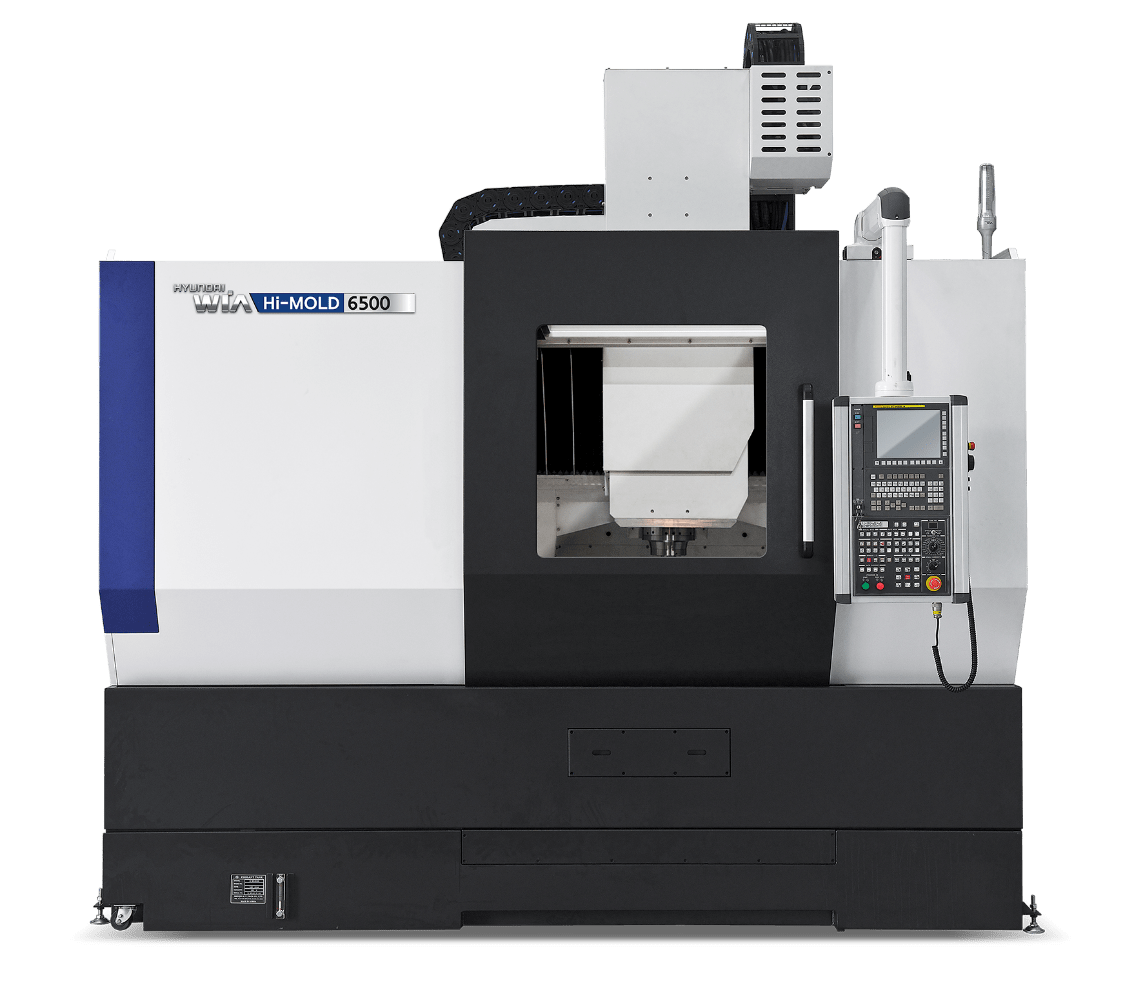

Hi-MOLD6500 Mold Machining

A VMC designed with cutting edge technology for high performance in mold machining. Equipped with a highly precise spindle with speeds up to 24,000 rpm, ball screw nut cooling system on all axes, and chip to chip time of 5 seconds.

- Table Size - 47.2" x 25.6"

- Max Load Capacity - 2,205 lbs

- Travel X/Y/Z - 43.3"/25.6"/21.7"

MORE INFO »

Hi-Mold Mold Machining

Hi-MOLD450 | Hi-MOLD560

The Hi-Mold Series are designed specifically for high speed, reliable mold machining. The built-in ultra-high speed (up to 40,000 rpm) main spindle creates high-quality surface finishing. Equipped with a SIEMENS 828D control, chip to chip time of 5.5 seconds, and a 24 tool ATC.

- Table Size - 33.7"x15.7" 450, 49.2"x23.6" 560

- Max Load Capacity - 660lbs 450, 1,760lbs 560

- Travel X/Y/Z - 23.6"/17.7"/17.7" 450, 39.3"/22"/17.7" 560

MORE INFO »

KF760BM Mold Machining

A high-speed VMC with a 12,000 rpm built-in precise spindle. Built with a separated column and magazine to prevent vibration, a semi-air-floating slide way, and vibration absorption through box guideways for more accurate machining.

- Table Size - 70.9"x27.6"

- Max Load Capacity - 4,409 lbs

- Travel X/Y/Z - 61"/29.9"/28.3"

MORE INFO »

5-Axis Machining Center

Hi-MOLD560/5A 5-Axis Machining Center

The Hi-Mold560/5A is designed specifically for high speed, reliable mold machining equipped with a 5-axis table. The built-in ultra-high speed (up to 40,000 rpm) main spindle creates high-quality surface finishing. Equipped with a SIEMENS 840D control, chip to chip time of 5.5 seconds, and a 24 tool ATC.

- Table Size - Ø19.7″x10.6″

- Max Load Capacity -550lbs

- Travel X/Y/Z - 39.3"/22"/17.7"

MORE INFO »

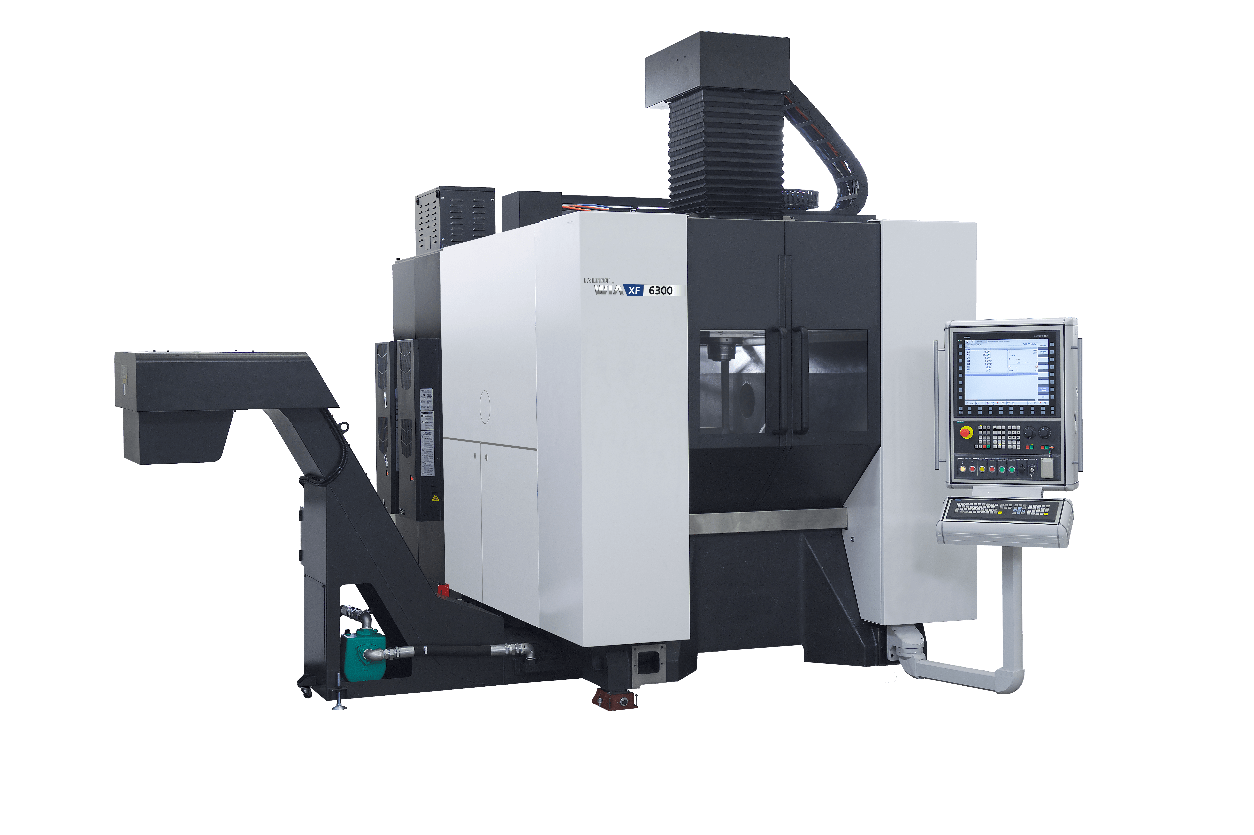

XF6300 5-Axis Machining Center

Perfect for composite and mold machining, containing the monoblock type bed structure and the X/Z axis is in a box-in-box structure to maintain accuracy and productivity. Equipped with a built-in DDM table, a 34-tool ring-type ATC that allows for a chip to chip time of 4.5 seconds, and a built-in HSK-A63 15,000 rpm spindle.

- Table Size - 24.8" x 15.7"

- Max Load Capacity - 1,323 lbs

- Travel X/Y/Z - 25.6"/23.6"/19.7"

MORE INFO »

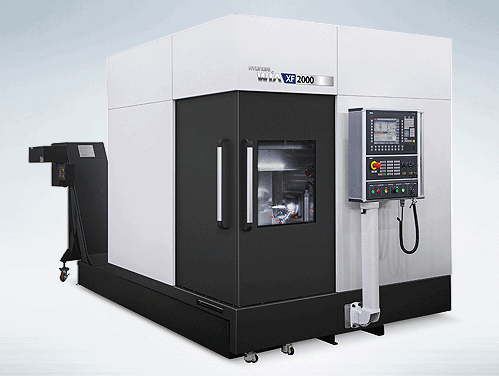

XF2000/i 5-Axis Machining Center

XF2000 | XF2000i

The XF2000/i is a high-speed, compact 5-axis simultaneous machining tool. Equipped with an integrated column for rigidity, cantilever-type table for easy chip disposal, a 40,000 rpm built in spindle (24,000 rpm XF2000i), and 2G accel/decel (1.2G XF2000i).

- Table Size - Ø7.9" , Ø10.2" XF2000i

- Max Load Capacity - 33lbs, 110 lbs XF2000i

- Travel X/Y/Z -11.8"/11.8"/7.9"

MORE INFO »

Hi-MOLD750/5A 5-Axis Machining Center

The Hi-Mold750/5A is designed specifically for high speed, reliable mold machining equipped with a 5-axis table. The built-in ultra-high speed (up to 15,000 rpm) main spindle creates high-quality surface finishing. chip to chip time of 4.5 seconds, and a 30 tool ATC.

- Table Size - Ø24.8″x19.7″

- Max Load Capacity - 1,102 lbs

- Travel X/Y/Z -25.6″/30.1″/20″

MORE INFO »

XF8500 5-Axis Machining Center

Perfect for composite and mold machining, the XF8500 is the ultimate 5-axis VMC for medium and large sized product. Contains an all-in-one bed structure and column structure, and the X/Z axis is in a box-in-box structure to maintain accuracy and productivity. Equipped with a built-in DDM table, a 34-tool ring-type ATC that allows for a chip to chip time of 4.98 seconds, and a built-in HSK-A63 9,000 rpm spindle.

- Table Size - 33.4" x 15.7"

- Max Load Capacity - 2,205 lbs

- Travel X/Y/Z - 33.4"/36.2"/23.6"

MORE INFO »

Hyundai Wia Horizontal Machining Centers

High Speed Machining Center

HS4000 Horizontal Machining Center

HS4000i | HS4000 | HS4000M

A HMC built for high-speed performance. The HS4000 series is equipped with a heavy-duty built-in spindle capable of speeds up to 15,000RPM. Built-in a Reverse "T" type bed, high-speed rotary pallet changer, a step type bed structure (HS4000M), and a tool and pallet changer with the latest servo technology (HS4000M).

- Pallet Size - 15.8" x 15.8"

- Max Load Capacity - 1,102 lbs,

- Travel X/Y/Z - 24.4"/22"/25.6"

- Spindle Speed - 12,000 rpm (HS4000i), 15,0000 rpm

MORE INFO »

HS5000M Horizontal Machining Center

HS5000M-1P | HS5000M | HS5000M/50-iP | HS5000M/50

A general-purpose HMC for efficient, continuous machining with the best in class rapid traverse rate on all axis of 60m/min. Equipped with a "T" Type Bed, heavy-duty built-in spindle, and a rotary turn high-speed APC. The HS5000M and HS5000M/50 have two pallets. Easily set-up for automation through a pallet lineup.

- Pallet Size - 19.7" x 19.7"

- Max Load Capacity - 1,764 lbs

- Travel X/Y/Z - 33.5"/27.6"/29.5"

- Spindle Speed - 15,000 rpm -1P/M, 12,000 50-1P and M/50

MORE INFO »

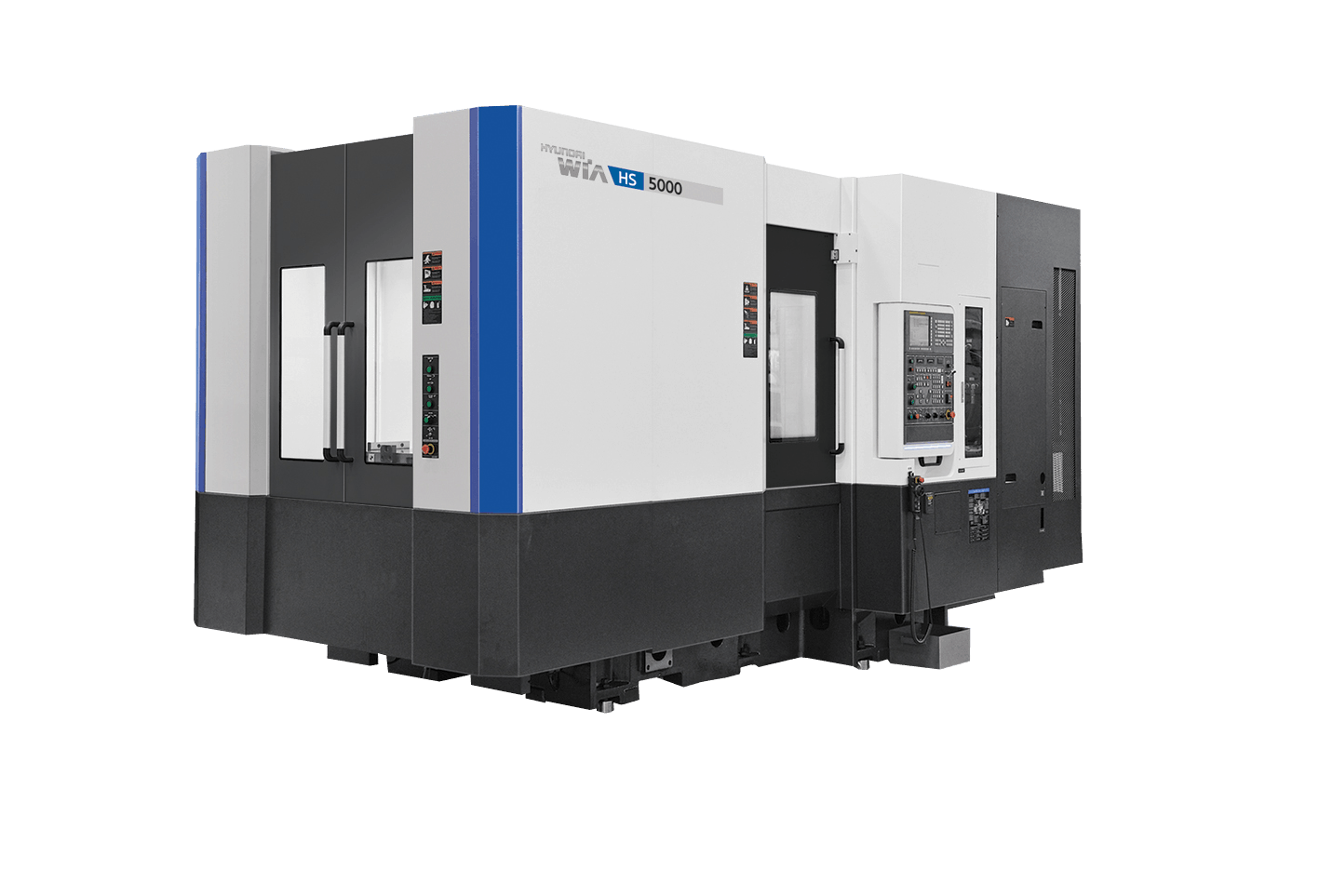

HS5000 Horizontal Machining Center

HS5000i | HS5000 | HS5000/50

A HMC built for high-speed performance. The HS5000 Series has a heavy-duty built-in spindle with a spindle rpm up to 15,000 depending on the model in the series. Built-in a Reverse "T" type bed, rotary turn type high-speed APC, and the best in class rapid traverse rate on all axis 60m/min.

- Pallet Size -19.7" x 19.7"

- Max Load Capacity - 1,102 lbs / 1,764 lbs (HS5000/50)

- Travel X/Y/Z - 33.5"/27.6"/29.5"

- Spindle speed - 12,000 rpm, 15,000 rpm (HS5000)

MORE INFO »

HS6300/8000 Horizontal Machining Center

Perfect for metalworking applications, is a high-speed HMC equipped with a 2 Step Gear built-in type 8,000RPM spindle. There are high speed, rigid roller guides available on all axes, and a 90 ATC driven by servo motor.

- Pallet Size - HS6300 24.8" x 24.8" HS8000 31.5" x 31.5"

- Max Load Capacity- HS6300 2 x 2,646 HS8000 2 x 3,527

- Travel X/Y/Z - 41.3"/34.4"/34.4"

- Spindle Speed - 8,000 rpm

MORE INFO »

Heavy Duty Cutting

KH50G/63G Heavy-Duty Cutting

A heavy-duty cutting HMC with a 2 Step Geared Main Spindle with an oiling cooling system to maintain accuracy. Equipped with an air semi-rising slideway on Z-axis, y-axis box guideways with 8 face contact, and a tool magazine that has capacity for a capacity up to 120 tools. The KH50G & KG63G has a specialty design column to minimize thermal displacement.

- Pallet Size - 19.7" x 19.7" KH50G, 24.8" x 24.8" KH63G

- Max Load Capacity - 2 x 1,764 lbs KH50G, 2 x 2,205 lbs KH63G

- Travel (X/Y/Z) - 29.9"/27.8"/25.6" KH50G, 37.4"/32.5"/29.9" KH63G

- Spindle Speed - 4,500 rpm

MORE INFO »

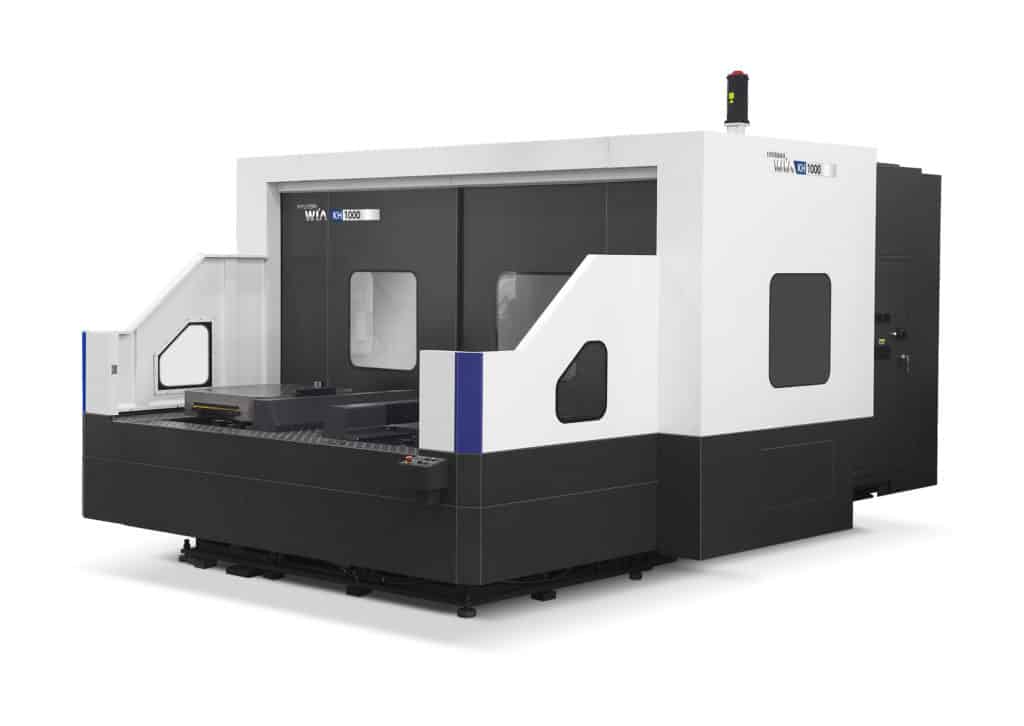

KH1000 Heavy-Duty Cutting

A heavy-duty cutting HMC with the largest work area in its class with large processing size of 74.8" x 59". Equipped with a Big Plus #50 2-step geared spindle available in high torque 8,000 and 4,500 rpm, a spindle oil cooling system to maintain high accuracy, and a shuttle type automatic pallet changer.

- Pallet Size - 39.4" x 39.4"

- Max load Capacity - 2 x 6,614lbs

- Travel (X/Y/Z) - 82.7"/53.1"/55.1"

- Spindle Speed - 8,000 rpm

MORE INFO »

KH80G Heavy-Duty Cutting

A heavy-duty cutting HMC with the largest work area in its class with large processing size of 45.2" and 45.2" high. Equipped with a 3 Step Gear Main Spindles perfect for heavy-duty cutting, a spindle oil cooling system to maintain accuracy, optimized guideways on each axis, a unique column to minimize thermal displacement, and a shuttle type automatic pallet changer.

- Pallet Size - 31.5" x 31.5"

- Max Load Capacity - 2 x 4,850 lbs

- Travel (X/Y/Z) - 49.2"/39.4"/33.5"

- Spindle Speed - 4,500 rpm

MORE INFO »

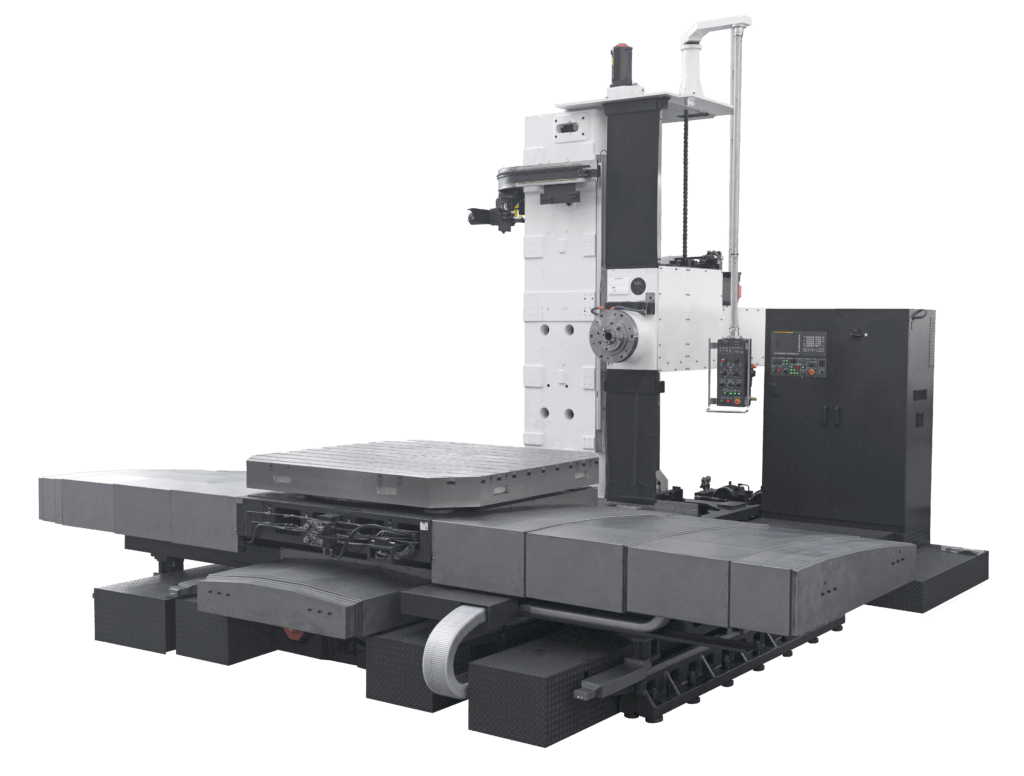

Boring Machines

KBN135 Boring Machining Center

A heavy-duty boring machine with a max load capacity of 22,046 lbs, designed for powerful cutting built in a rigid design. With a single unit bed for X and Z axis for ultra-precision, and a 3-step gear drive the main spindle. The KBN135 is equipped with a standard linear and rotary scales for ultra-precision, and with the W-axis maximum travel of 27.5" you get optimal boring capabilities.

- Pallet Size - 78.7" x 70.9"

- Travel (X/Y/Z) - 118.1"/78.7"/63"

- Spindle Speed - 2,000 rpm

MORE INFO »

KBM135C Boring Machining Center

A heavy-duty boring machine with a max load capacity of 33,069lbs, designed for powerful cutting built in a rigid design. The KBN135C has a movable column structure for high-load, and a 3-step gear drives the main spindle for heavy-duty cutting. Equipped with standard linear and rotary scales for ultra-precision, and you get optimal boring capabilities with the W-axis maximum travel of 27.5".

- Pallet Size - 78.7" x 70.9"

- Travel X/Y/Z - 118"/78.7"/63"

- Spindle Speed - 2,000 rpm

MORE INFO »