The Tsugami SS327-III-5AX , a 32mm B-axis sliding headstock Swiss type lathe, is the ultimate Swiss turn lathe for complex shaped parts. The Tsugami Mach III version brings enhancements to successful the SS327 platform. The enhancements include larger linear guides,  ribs in the base casting, a 4GB server, Thermal Displacement Compensation sensors throughout, and a 3 toggle clamping system. So what make this SS327-III so special? The servo-driven modular B-axis. The B-axis allows complete complex part machining in a single set-up, but it also turns the Swiss lathe into a multitasking turning center. This allows drilling, tapping, and end milling at any angle.

ribs in the base casting, a 4GB server, Thermal Displacement Compensation sensors throughout, and a 3 toggle clamping system. So what make this SS327-III so special? The servo-driven modular B-axis. The B-axis allows complete complex part machining in a single set-up, but it also turns the Swiss lathe into a multitasking turning center. This allows drilling, tapping, and end milling at any angle.

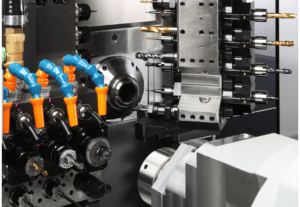

This machine has an easy to set-up modular tool zone on the B-axis and sub side for fast changeover times. The Modular Tool Zone uses cartridge type live tools with 38 tool  positions. Eight backworking live tools and a three toggle clamping system allow full 5-axis machining. The highly rigid bed features a heavy duty casting for highly accurate, high speed machining.

positions. Eight backworking live tools and a three toggle clamping system allow full 5-axis machining. The highly rigid bed features a heavy duty casting for highly accurate, high speed machining.

Another reason the SS327-III-5AX is the ultimate Swiss type turn lathe, is that it is convertible. This machine can be run as a traditional sliding headstock Swiss Type Lathe using the guide bushing or using the included chucker kit. To increase the flexibility of this machine, the chucker can use drawn bar stock instead of centerless ground stock that reduces remnant length.

Ideal Applications

This machine is ideal for applications requiring sculpted geometries and bone screws at any helix. Technical Equipment Sales applications team has a lot of knowledge and experience working with the SS327-III-5AX. Our experienced team can assist you with any questions you have about the applications and programming needed to produce these parts.

Technical Equipment Sales provides trusted service and support years after your machine is installed. We are there for you to help you do more with less. If you would like more information on the SS327-III-5ax, our service department or our applications department, please contact us today at [email protected].

Machine Specifications

Maximum Bar Stock – 32mm, 1.25in

Sliding Headstock / Guide Bushing – YES

CONVERTIBLE: Run w/o Guide Bushing (chucker) – YES

Max Headstock Stroke w/ Guide Bushing – 330mm / 12.99″

Max Headstock Stroke w/o Guide Bushing – 70 mm / 2.74″

# Axes – 7

# Tool Positions (std / max) – 38

# Live Tool Positions (std / max) – 18/20

Control – FANUC 31i-B5

Main Spindle Speed – 200-8,000 rpm

Sub Spindle Speed – 200 – 8,000 rpm

Live Tool Speed – 7,000 rpm (B-axis tools), 6,000 rpm (other)

Main Spindle Motor – 3.7 / 5.5 kW

Weight – 4,000 kg / 8,800 lbs

Footprint W x D x H – 84.6″ x 50.3″ x 79.1″

Who is Tsugami / Rem Sales?

Tsugami Rem/Sales is the exclusive North American importer of Precision Tsugami machines tools. Precision Tsugami is located in Tokyo, Japan. They specialize in manufacturing high-precision CNC Lathes, Turning Centers, Machining Centers and Multi-Tasking machines for small parts. Precision Tsugami sets the standards for Swiss Turning of small diameter parts.