Protect Your Investment

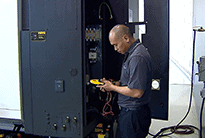

Protect your capital investment and maximize your return by keeping your equipment in top operating condition. Technical equipment offers a Preventative Maintenance package to keep your machines up and running at a reduced labor rate. With the COVID-19 Pandemic still in effect, many machines have been idle or less productive during this time. CNC machines are meant and made to run on a regular basis. The prolonged shutdown or slow down can lead to machine issues. Avoid costly downtimes because routine preventative maintenance was not performed. Our factory trained Field Service Engineers know what issues to look for and find what could potentially slow or stop your production down the line. We provide tailored packages for your specific machine needs.

Protect your capital investment and maximize your return by keeping your equipment in top operating condition. Technical equipment offers a Preventative Maintenance package to keep your machines up and running at a reduced labor rate. With the COVID-19 Pandemic still in effect, many machines have been idle or less productive during this time. CNC machines are meant and made to run on a regular basis. The prolonged shutdown or slow down can lead to machine issues. Avoid costly downtimes because routine preventative maintenance was not performed. Our factory trained Field Service Engineers know what issues to look for and find what could potentially slow or stop your production down the line. We provide tailored packages for your specific machine needs.

What comes with a Preventative Maintenance package?

Our Preventative Maintenance packages includes a lot more than what regular maintenance entails. So, that means more than just changing oils and the filters. Our Preventative Maintenance (PM) packages include a full CNC machine alignment check and thorough analysis including electronics, motors, pumps, hydraulics, lubrication, axis movement, spindle, tool change functions, alignments and much more.

When our expert technicians come in to perform a PM and find necessary repairs, we can source parts quickly to fix the necessary changes. Our dedicated inside Parts Administrators can locate and source parts for you quickly to avoid unnecessary and costly machine downtimes!

How to purchase a Preventative Maintenance Package from Technical Equipment?

To purchase a Preventative Maintenance package for your capital equipment please reach out to our service department through our website, by filling out the form below, emailing [email protected], or calling us at 513-874-0160. Our service department is ready to assist you by providing a personalized PM package just for you. We help determine the service intervals needed for your specific machine – daily, weekly, monthly, and annually. Each PM package is dependent on customer machine run hours. Our standard program starts at 2,000 run hours, but that can vary per machine. We can also prepare a recommended parts list for items that need to be changed when our technicians perform the PM to save you time and effort. You can also contact our parts department for quotes on required PM parts. Put our team to work for you, and your capital equipment needs!

Interested in Preventative Maintenance for your machines? Fill out the form below, and we will get back to you!